- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

NP Impact Crusher

Processing Capacity:150-1970t/h

Feed Particle Size:≤800mm

Applicable Materials:Limestone, quartz stone, dolomite, iron ore, concrete, coal, etc.

Application Scope:Sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

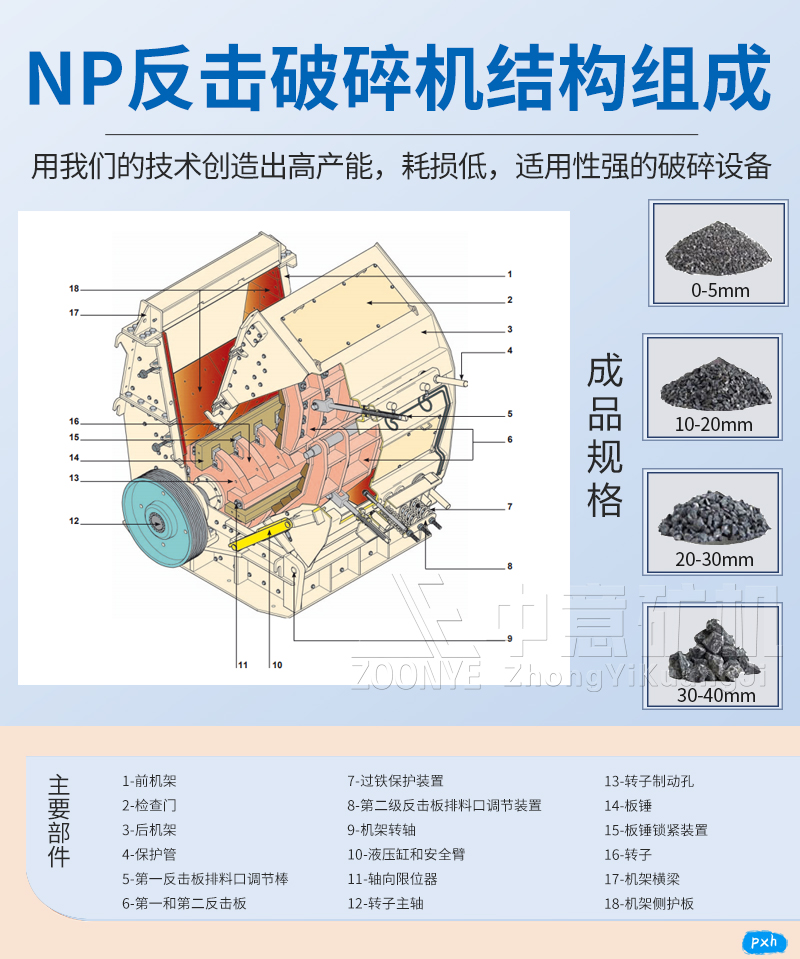

NP impact crusher

The NP series impact crusher absorbs foreign technology and optimizes the design based on domestic actual conditions. The equipment adopts a combination of heavy-duty rotor design, high wear-resistant materials and large crushing cavity design, which improves production efficiency under the same conditions. At the same time, production costs and consumption of wearing parts are reduced. NP series impact crusher is widely used to crush various soft and medium-hard ores. This series of products currently has 8 models, divided into coarse crushing series and medium crushing series, with output ranging from 130 tons per hour to 1970 tons per hour.

Real shots of NP impact crusher manufacturers

500 tons per hour NP impact crusher

NP1520 impact crusher

NP counter attack side display

The customized 300 tons per hour counterattack crusher will be shipped soon.

NP impact crusher manufacturer supplies

NP series impact crusher

The master worker is inspecting the equipment

NP impact crusher can handle hundreds of materials

Advantages And Characteristics

1. High-quality plates and wear-resistant parts reduce wear and improve production efficiency under various working conditions; advanced processing technology and technology are the basis for high-quality equipment performance.

2. The sturdy heavy-duty rotor structure improves the equipment's processing capacity and crushing ratio; the high-quality welded structure ensures that the machine can withstand large impact forces and achieve good crushing effects.

3. The product has strong versatility. The two-chamber crushing equipment can be converted into a three-chamber crushing equipment by adding a grinding frame without replacing other parts, reducing the user's secondary investment.

4. The main shaft is made of high-quality forgings for finishing, which makes the equipment operation more reliable and subsequent maintenance easier.

5. Hydraulic cover opening and hydraulic auxiliary adjustment of the gap between the impact plate and the plate hammer reduce labor intensity and shorten downtime.

6. Wide adjustment range and diversified crushing specifications. The size of the discharged particles can be adjusted by adjusting the rotor speed, adjusting the gap between the impact plate and the plate hammer, etc. to achieve diversified crushing specifications.

7. The wearing parts have little wear and long service life. The wear of the plate hammer only appears on the side facing the material. When the rotor rotates, the material will fall to the surface of the plate hammer (the striking surface). The back and sides of the plate hammer are not affected by the impact. Wear, even on the side facing the material, is very little.

Working Principle

Working principle of NP impact crusher

When the machine is working, driven by the motor, the rotor rotates at high speed. When the material enters the plate hammer action area, it is crushed by impact with the plate hammer on the rotor, and then is thrown to the counterattack device for crushing again, and then passes from the counterattack liner. It bounces back to the plate hammer action area for re-crushing. This process is repeated. The materials from large to small enter the first, second and third impact chambers for repeated crushing until the materials are crushed to the required particle size and discharged from the discharge port. Adjusting the gap between the impact frame and the rotor can change the material discharge particle size and material shape.

Selection of wear-resistant parts for NP impact crusher

NP impact crusher wear parts

NP impact crusher mainly contains three different wear-resistant parts: blow hammer, impact plate liner and frame side liner. The choice of impact crusher liner type and material is of great significance to its operating performance. Liners need to be selected based on the type of material, abrasiveness, external factors and feed particle size, as well as the required product. The material machine options of the lining plate include manganese steel, martensitic steel and high chromium cast iron; in the applications of coarse crushing and construction waste recycling crushing (waste steel bars may enter the crushing cavity), the continuous impact strength and impact strength of the lining plate are It is very important, so choose materials with better performance.

In the NP impact crusher, the board hammer is a component that bears large mechanical stress, accounting for about 60%-70% of the wear cost. When the center of gravity of the ore particles enters the rotation trajectory of the board hammer, central impact crushing can occur. At this time, the energy utilization rate is high. The edge impact force produced by the blow hammer is more than the center impact force, causing the edge to be rounded quickly. Depending on the actual operating conditions, the central impact effect can be increased by increasing the height of the plate hammer and adjusting the rotation speed.

Technical Parameter

| Type | Model | Rotor specifications | Feeding port size(mm) | Rotor weight | Maximum feeding particle size(800mm) | Maximum feeding particle size(600mm) | Rated installed power | |||

| Final product200mm | Final product100mm | Final product200mm | Final product100mm | Rated installed power | Maximum installed power | |||||

| Coarse chopped series | NP1313 | φ1300x1300 | 1320x1225 | 6.3 | 450 | 300 | 480 | 320 | 200 | 250 |

| NP1415 | φ1400x1500 | 1540x1320 | 8.2 | 560 | 365 | 600 | 400 | 250 | 315 | |

| NP1620 | φ1600x2000 | 2040x1634 | 15.9 | 870 | 570 | 930 | 620 | 400 | 500 | |

| NP2023 | φ2000x2300 | 2310x1986 | 28.3 | 1780 | 1160 | 1970 | 1270 | 1000 | 1000 | |

| Medium broken series | NP1110 | φ1100x1000 | 1020x820 | 3.1 | 190 | 150 | 210 | 130 | 160 | 200 |

| NP1213 | φ1200x1300 | 1320x879 | 4.9 | 250 | 200 | 280 | 180 | 200 | 250 | |

| NP1315 | φ1300x1500 | 1540x930 | 6.4 | 315 | 250 | 350 | 225 | 250 | 315 | |

| NP1520 | φ1500x2000 | 2040x995 | 10.4 | 500 | 400 | 560 | 360 | 400 | 500 | |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)