- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

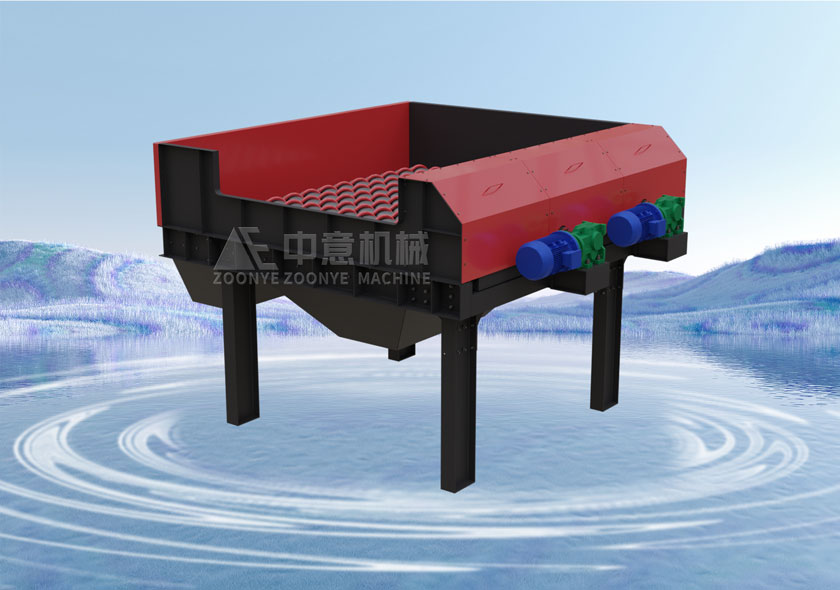

Spiral Screen

Processing Capacity:60-600m³/h

Feed Particle Size:≤300mm

Applicable Materials:Construction waste, decoration waste, old waste, bulky waste, etc.

Application Scope:Building materials, cement, chemicals, waste treatment plants

- +8615238639909

- 7 * 24-hour Service Hotline

Spiral Screening Machine

The spiral screening machine is a machine specially designed for the sorting and processing of domestic waste. It can sort long hard materials such as wooden rods, iron pipes, etc. and small pieces of materials according to different specific gravity, hardness, size, and shape. Separate them separately to reduce the load on subsequent sorting equipment. The pitch and diameter determine the size of the screening, which can be selected from a range, and the operating speed of each spiral shaft can be automatically adjusted according to material composition, humidity, etc.

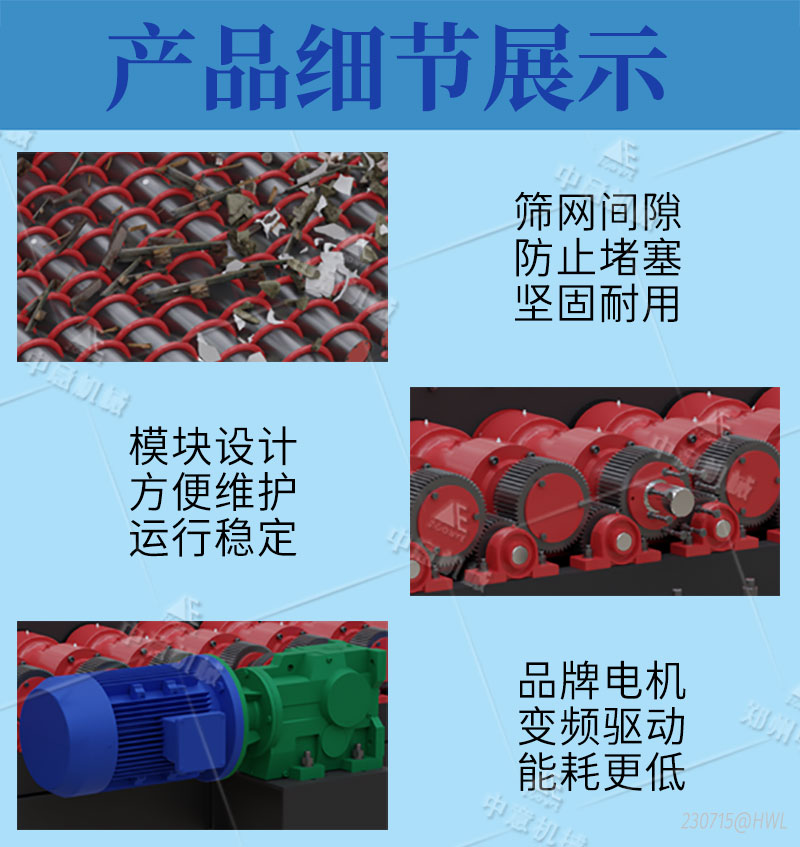

Features

1. The screen surface is sturdy and durable, and wet materials will not block the screen holes.

2. The equipment operates smoothly, without vibration and low noise;

3. The material advancement speed is fast, the processing capacity is larger than that of the drum screen, the floor space is smaller, and the screening efficiency is higher

4. The motor can be driven by variable frequency, which consumes less energy;

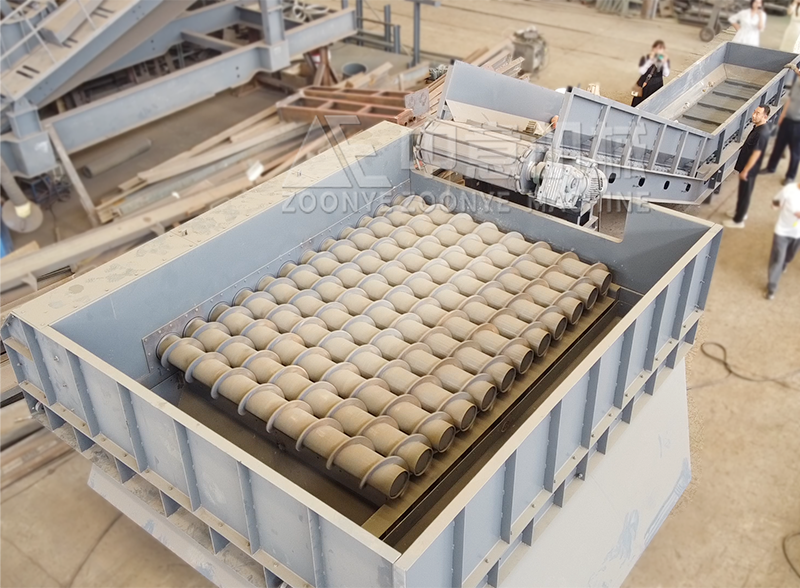

Real Shots From The Manufacturer

Spiral Screen Sorting Equipment

Customer On-site Test Machine With Materials

Working Principle

When the spiral screening machine equipment is started, the screw rotates, and the materials entering the screen surface are pushed by the threaded ribs on the screw, and pass through the screen holes designed between the threaded ribs or grooves and the threaded grooves or ribs on the adjacent screw. , to obtain products under the screen, large-grained materials are discharged from the upper part of the spiral surface, and small-grained materials are discharged from the lower part of the spiral surface, thereby achieving the functions of grouping and separation.

Product Details

Product Details

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)