- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

HPZ Multi-cylinder Hydraulic Cone Crusher

Processing Capacity:100-900t/h

Feed Particle Size:<390mm

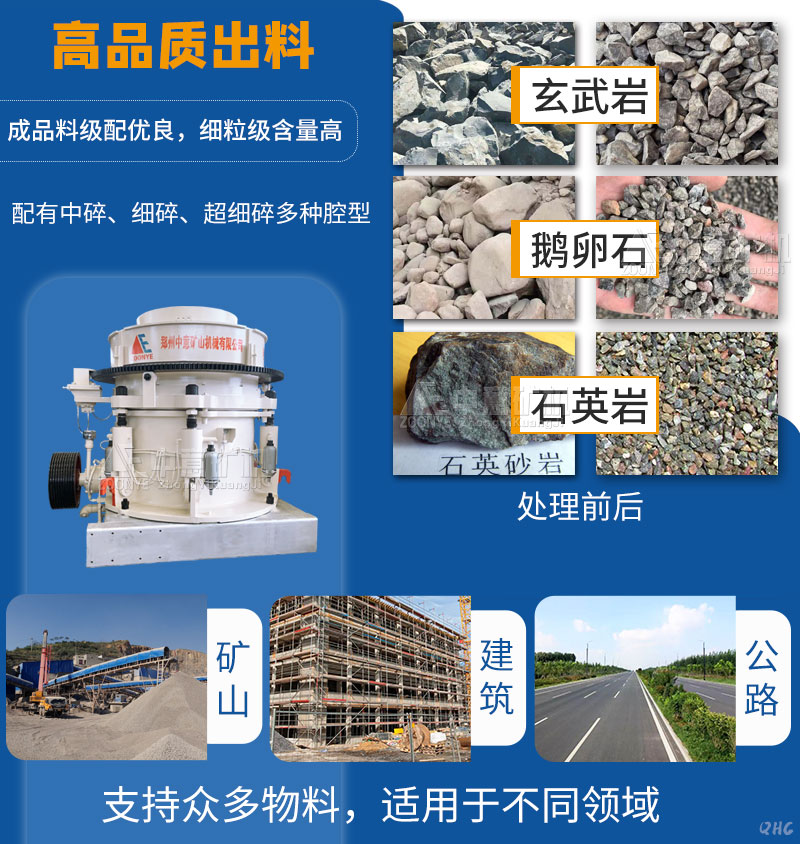

Applicable Materials:Quartz stone, river pebbles, calcite, dolomite, granite, basalt, iron ore, limestone, diabase, bluestone, construction waste, etc.

Application Scope:Used in mining, building materials, transportation, energy, chemical industry and other industries.

- +8613503852957

- 7 * 24-hour Service Hotline

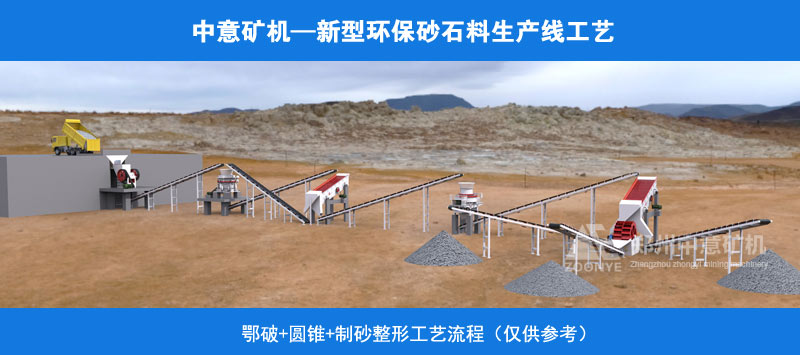

HP series multi-cylinder hydraulic cone crusher display diagram

This production line is for reference only. The specific process configuration needs to be determined according to the nature, hardness, type of finished product, etc. of the material.

HP multi-cylinder hydraulic cone crusher is a new type of cone crusher developed by our company. It is used to crush high-hardness materials with strict requirements on product shape. This machine is superior to traditional spring cone crushers.

Multi cylinder hydraulic cone breaking can handle materials

HP multi-cylinder hydraulic cone crusher

Multi-cylinder hydraulic cone crusher workshop product display

Large hydraulic multi-cylinder cone crusher equipment

HP multi-cylinder hydraulic cone crusher

Multi-cylinder hydraulic cone crusher

Multi-cylinder hydraulic cone crusher

Customized multi-cylinder hydraulic cone crusher delivered to customers in Zhengzhou

Advantages And Characteristics

Fixed shaft structure design, large crushing force and low equipment infrastructure investment. Laminated crushing chamber design, product size is uniform, cubic, low energy consumption, PLC + touch screen automatic control system ensures safe operation of the equipment. Equipped with a remote touch screen operation interface, which can display real-time working status. The rolling mortar wall does not require fillers, and replacement is quick and convenient. All components can be The top and sides can be removed to facilitate equipment maintenance. Hydraulic motor adjustment and exhaust port adjustment are easy to operate. Hydraulic lubrication combined gas station is small in size and simple in wiring.

Working Principle

Working principle of multi-cylinder hydraulic cone crusher

During operation, the pulley or coupling, drive shaft and tapered section are driven by the rotation of the motor, causing the eccentric shaft to rotate periodically under the axis. After the material enters the crushing chamber from the material inlet, it is crushed by the mutual impact of the eccentric shaft and the rolling wall. The hydraulic safety system can eliminate the faulty parts of the support casing and the fixed tapered part through hydraulic pressure when there is an iron failure or boring phenomenon in the machine, greatly reducing the maintenance rate, improving production efficiency, and at the same time exerting a good insurance function.

Technical Parameter

| Model | Cavity type | Adjustment range of discharge port(mm) | Feeding port size(mm) | Production capacity(t/h) | Power(kw) |

| HPZ300 | short head | 10 | 77 | 100-150 | 200 |

| standard | 20 | 211 | 200-300 | ||

| HPZ400 | short head | 10 | 92 | 120-180 | 315 |

| standard | 25 | 252 | 250-400 | ||

| HPZ500 | short head | 13 | 95 | 180-250 | 355 |

| standard | 25 | 286 | 350-500 | ||

| MP800 | short head | 13 | 155 | 200-430 | 600 |

| standard | 32 | 297 | 450-700 | ||

| MP1000 | short head | 10 | 169 | 220-510 | 655 |

| standard | 38 | 390 | 600-900 |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)