- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

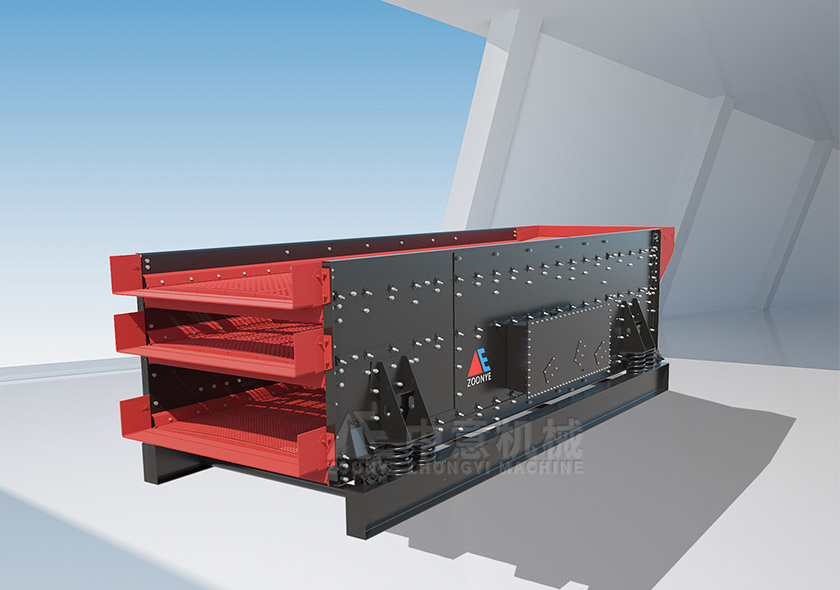

TES Series Three-axis Horizontal Vibrating Screen

Processing Capacity:50-550t/h

Feed Particle Size:150mm

Applicable Materials:River pebbles, coal gangue, granite, iron ore, etc.

Application Scope:It is widely used in the production and processing of sand and gravel aggregates in hydropower, highways, railways, construction and other fields and in material classification and screening operations in construction waste treatment systems.

- +8613503852957

- 7 * 24-hour Service Hotline

The TES series three-axis horizontal vibrating screen is developed by absorbing the same type of vibrating screen technology at home and abroad. Because it is installed horizontally and takes up little space on site, it is widely used in metallurgy, building materials, transportation and other industries. It is an ideal equipment for mobile crushing stations. . The three-axis drive can make the screen machine produce ideal elliptical motion. It has the advantages of circular vibrating screen and linear vibrating screen. It has the characteristics of good screen penetration, large processing capacity and small installation height. The vibration can be selected according to the actual material conditions. trajectory, which is more advantageous for materials that are difficult to screen. It is an ideal equipment for various mines, quarries, and mobile screening stations.

Three-axis horizontal vibrating screen

More efficient screening

Elliptical motion with adjustable amplitude

Three-axis drive ensures smooth operation

Horizontal installation method, saving space

Advantages And Characteristics

(1) The three-axis drive can make the screen machine produce ideal elliptical motion with adjustable amplitude. The oscillation track can be selected according to the actual material conditions, which is more advantageous for materials that are difficult to screen.

(2) The three-axis drive forces synchronous vibration, which enables the screen machine to achieve a stable operating condition, which is particularly beneficial for screening that requires a large processing capacity.

(3) The three-axis drive improves the stress state of the screen frame, reduces the load on a single bearing, and evenly stresses the side plates, further improving the reliability and service life of the screen machine.

(4) Because of its horizontal installation, it effectively reduces the height of the unit and can well meet the needs of large and medium-sized mobile screening units.

(5) The bearing is lubricated with thin oil, which effectively reduces the bearing temperature and increases the service life.

(6) For the same screening area, the output of the elliptical vibrating screen can be increased by 1.3-2 times.

Working Principle

The three-axis horizontal vibrating screen uses a three-axis block eccentric vibrator as the excitation source. The three axes of the exciter are equipped with counterweight blocks of the same specifications. The gears are forced to be synchronized. The structure is compact and stable, and the energy consumption is low. The power is transmitted from the motor to the driving shaft through the pulley, and the synchronous gear forces each axis to maintain a stable phase difference, thereby generating an exciting force and forcing the screen box to perform forced continuous elliptical motion. The material uses the power of elliptical vibration to continuously beat, stratify and separate along the circumferential direction of the horizontal screen surface. When thrown, the material is loosened and stratified while moving forward, and the work of particle size classification and forward transportation is completed during the repeated throwing process.

Technical Parameter

| Model | Screen surface specifications width x length(mxm) | Screen area(㎡) | Vibration frequency(r/min) | Double amplitude(mm) | Processing power(m3/h) | Motor function(kw) |

| TES1860 | 1.8x6.0 | 10.8 | 645-970 | 11-15 | 50-320 | 30 |

| TES2060 | 2.0x6.0 | 12 | 75-385 | 37 | ||

| TES2460 | 2.4x6.0 | 14.4 | 90-550 | 40 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)