- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

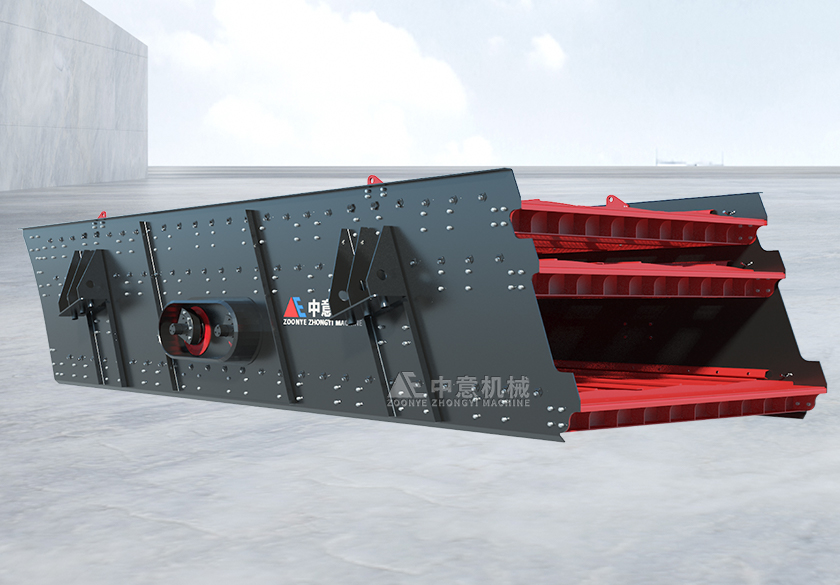

YK Series Circular Vibrating Screen

Processing Capacity:20-1000t/h

Feed Particle Size:≤600mm

Applicable Materials:River pebbles, iron ore, coal gangue, granite, basalt and other materials

Application Scope:It is widely used in product classification in mining, building materials, transportation, energy, chemical and other industries.

- +8615238639909

- 7 * 24-hour Service Hotline

The circular vibrating screen equipment produced by Zhongyi Mining Machinery is a kind of screening machine equipment that is widely used in production lines such as crushing, sand making and mineral processing. From the aspects of design, technology, work experience, performance, etc., the circular vibrating screen equipment produced by Zhongyi Mining Machinery has been Become a mature product. The material of the circular vibrating screen is made of high-strength manganese steel, which has strong impact resistance for materials with high hardness and large pieces. It can be equipped with rubber springs according to the actual situation to effectively reduce the noise during operation. There is enough noise during the screening process. The bouncing force prevents the material from falling into slots, which affects the screening penetration rate. Circular vibrating screens are divided into single-layer and double-layer types, and are mostly used in mining, building materials, transportation, energy, chemical and other industries for screening operations.

Circular vibrating screen manufacturer

YK series circular vibrating screen

Circular vibrating screen manufacturer

Sand and gravel circular vibrating screen

Actual shot of circular vibrating screen workshop

Sino-Italian circular vibrating screen exported to Kenya

Circular vibrating screen delivery

Advantages And Characteristics

1. Adopt tire coupling, flexible connection, smooth operation.

2. The structure is simple and uses block eccentricity as the excitation force. It has strong excitation force, low power consumption and low noise.

3. The screen beams and screen boxes are made of high-strength bolts, with simple structure and convenient and quick maintenance.

4. Ring groove rivet connection, strong and durable.

5. The equipment is given a thin oil softening device, which reduces the wear and tear of the equipment.

Henan cobblestone crushing and sand making project introduces multiple circular vibrating screens from China and Italy

Guangdong 200 tons per hour river pebble sand production line

Qinghai Xining gravel production line

Working Principle

The motion trajectory of the screen box of the circular vibrating screen is circular or elliptical. The circular vibrating screen uses an inertial exciter to generate vibration, giving it a power and inertial force, and operates under the interaction of the two forces. The vibration source is generally an exciter driven by a motor. The circular vibrating screen is a single-axis vibrator. The main shaft fixed on the screen box is driven by the motor to rotate at high speed. The eccentric body installed on the main shaft rotates accordingly, generating centrifugal inertia force. The freely vibrating screen box is caused to vibrate in an approximately circular trajectory.

Technical Parameter

| Model | Number of screen layers | Screen inclination angle(℃) | Screen area(㎡) | Vibration frequency(r/min) | double amplitude(mm) | Processing power(m3/h) | Motor function(Aw) |

| 3YK1225 | 3 | 15 | 2.88 | 970 | 6-8 | 20-120 | 4 |

| YK1235 | 1 | 15 | 4.2 | 970 | 20-150 | 5.5 | |

| 2YK1235 | 2 | 15 | 4.2 | 970 | 20-150 | 5.5 | |

| 3YK1235 | 3 | 15 | 4.2 | 970 | 20-150 | 7.5 | |

| 4YK1235 | 4 | 15 | 4.2 | 970 | 20-150 | 7.5 | |

| YK1545 | 1 | 15 | 6.75 | 970 | 20-150 | 11 | |

| 2YK1545 | 2 | 17.5 | 6.75 | 970 | 22-150 | 15 | |

| 3YK1545 | 3 | 17.5 | 6.75 | 970 | 22-150 | 15 | |

| 4YK1545 | 4 | 17.5 | 6.75 | 970 | 22-150 | 18.5 | |

| 2YK1860 | 2 | 20 | 10.8 | 970 | 32-350 | 15 | |

| 3YK1860 | 3 | 20 | 10.8 | 970 | 32-350 | 22 | |

| 4YK1860 | 4 | 20 | 10.8 | 970 | 32-350 | 30方管框架 | |

| 2YK2160 | 2 | 20 | 12.6 | 970 | 66-720 | 22 | |

| 3YK2160 | 3 | 20 | 12.6 | 740 | 66-720 | 30方管框架 | |

| 3YK2170 | 3 | 20 | 12.6 | 740 | 66-720 | 30 | |

| 4YK2160 | 4 | 20 | 12.6 | 740 | 66-720 | 30 | |

| 2YK2460 | 2 | 20 | 14.4 | 740 | 75-750 | 37 | |

| 3YK2460 | 3 | 20 | 14.4 | 740 | 75-750 | 37 | |

| 4YK2460 | 4 | 20 | 14.4 | 740 | 75-750 | 37 | |

| 2YK2470 | 2 | 20 | 14.4 | 970 | 80-800 | 37 | |

| 3YK2470 | 3 | 20 | 14.4 | 970 | 80-800 | 37 | |

| 4YK2470 | 4 | 20 | 14.4 | 970 | 80-800 | 45 | |

| 2YK2475 | 2 | 20 | 16 | 970 | 120-900 | 37 | |

| 3YK2475 | 3 | 20 | 16 | 970 | 120-900 | 37 | |

| 4YK2475 | 4 | 20 | 16 | 970 | 120-900 | 45 | |

| 3YK3060 | 3 | 20 | 17.4 | 740 | 200-900 | 45 | |

| 4YK3060 | 4 | 20 | 17.4 | 740 | 200-900 | 45 | |

| 2YK3075 | 2 | 20 | 18 | 970 | 200-900 | 37 | |

| 3YK3075 | 3 | 20 | 18 | 970 | 300-1280 | 45 | |

| 4YK3075 | 4 | 20 | 18 | 970 | 300-1280 | 45 | |

| 2YK3060 | 2 | 20 | 17.4 | 740 | 300-1280 | 37 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)