- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

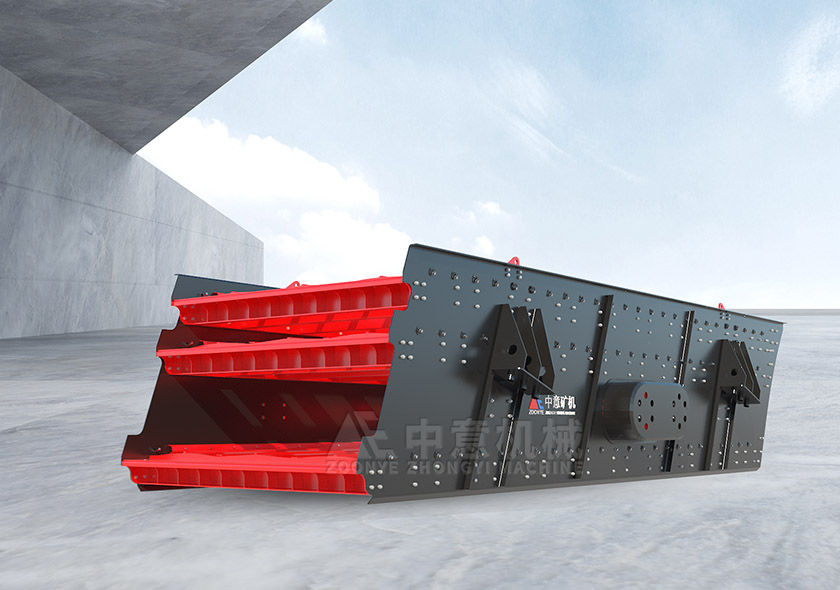

FYK Series Thin Oil Lubricated Vibrating Screen

Processing Capacity:28-1800t/h

Feed Particle Size:≤500mm

Applicable Materials:Sand and gravel aggregate, recycled aggregate, coal mine...

Application Scope:Sand and gravel plant, refractory material plant, mineral processing plant...

- +8613503852957

- 7 * 24-hour Service Hotline

The FYK series thin oil circulating lubrication vibrating screen is a kind of screening equipment in the crushing industry with high screening efficiency, stable and reliable operation. It is indispensable for the classification and screening of sand and gravel production line products. This equipment relies on the lubrication structure, which greatly reduces the The operating temperature of the bearing plays a decisive role in the continuous and stable operation of the equipment. Compared with grease lubrication, thin oil lubrication can improve the performance of the vibrating screen's lubrication system. Because thin oil lubrication is not only lubrication, but also can take away the heat generated by vibration friction of the vibrating screen while lubricating it, and play a role in heat dissipation. The circular vibrating screen of Zhongyi Mining Machinery adopts thin oil lubrication method, which effectively extends the service life of the bearings. As the main screening equipment of the screening system, Zhongyi FYK series vibrating screen has been widely used in large sand and gravel yards, ore sorting, coal mine screening and chemical raw material processing.

Thin oil lubricated vibrating screen

Thin oil lubricated vibrating screen

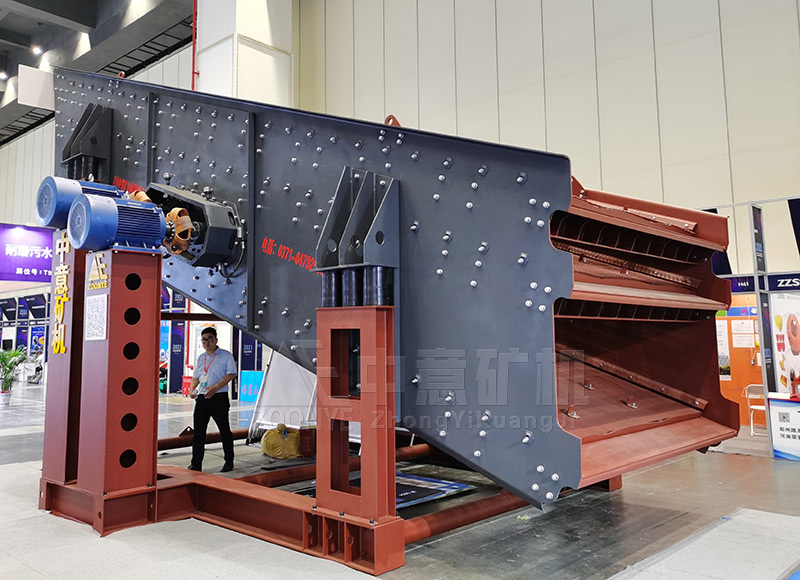

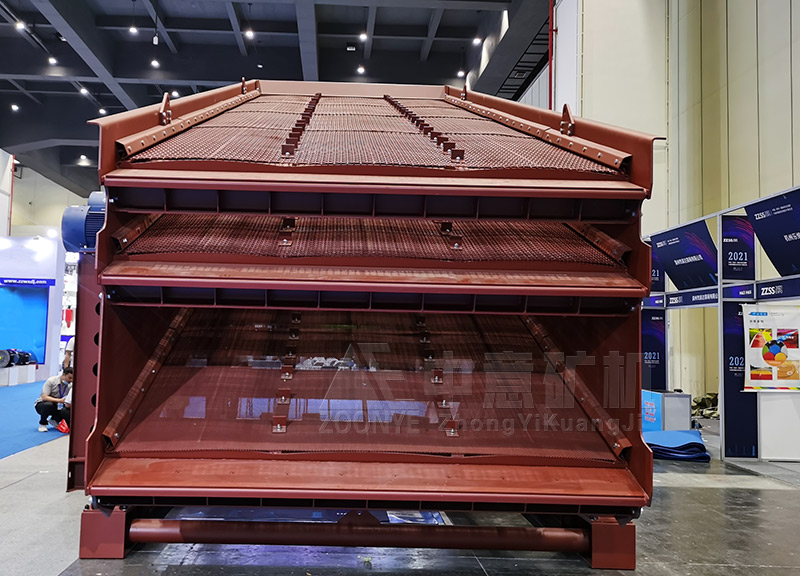

Actual shot of thin oil lubricated vibrating screen equipment

Large mining vibrating screen

Sand and gravel vibrating screen

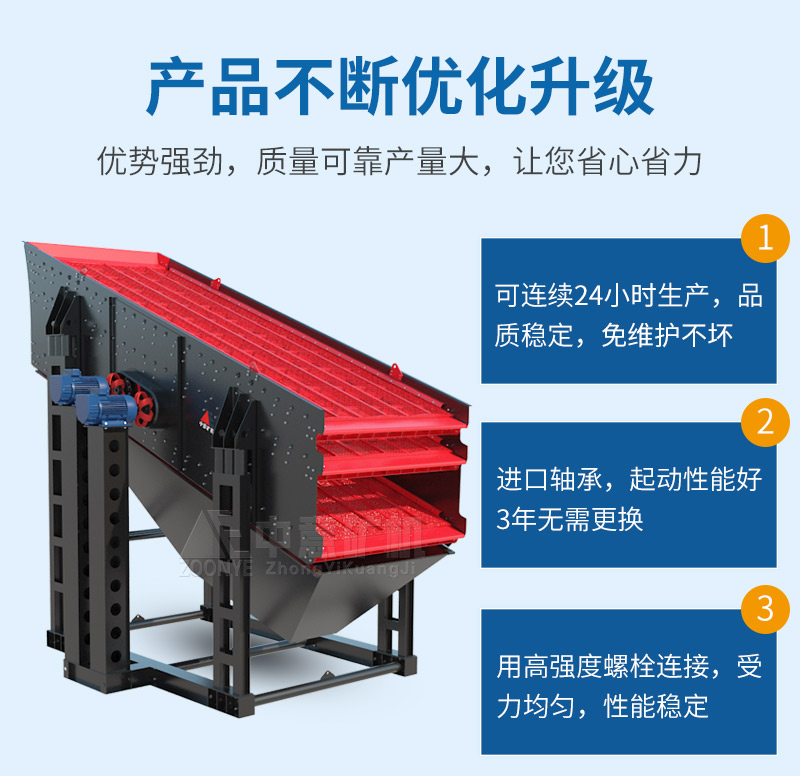

Advantages And Characteristics

Advantages of thin oil lubricated vibrating screen

1. Large processing capacity and high screening efficiency;

2. The vibrator adopts a bearing thin oil lubrication device to make the equipment more lubricated;

3. The vibrator can be disassembled and assembled as a whole, resulting in short maintenance time and higher output;

4. The side plate of the screen machine is made of whole plate cold work, no welding, high strength and long service life;

5. The impact force is small and the power is high, causing little wear on wear-resistant equipment.

Working Principle

Working principle of thin oil lubricated screen

The movement of the vibrating screen is driven by an electric motor through a triangle belt to drive an eccentric mass exciter, which causes the screen bed to perform periodic asymmetric reciprocating mechanical vibrations, causing the material layer on the screen surface to loosen and be thrown away from the screen surface, causing the Fine materials can fall through the material layer and be separated through the screen holes, and the materials stuck in the screen holes will be vibrated out. The fine materials will move to the bottom and be eliminated through the screen.

Technical Parameter

| Model | Number of screen layers | Screen inclination angle(°) | Sieve hole size(㎡) | Vibration frequency(r/min) | Double amplitude(mm) | Processing power(m³/h) | Motor Power(kw) |

| F5YK1548-2P | 2 | 17.5 | 7.2 | 970 | 6-8 | 28-270 | 15 |

| F5YK1548-3P | 3 | 17.5 | 7.2 | 970 | 6-8 | 28-270 | 15 |

| F5YK1548-4P | 4 | 17.5 | 7.2 | 970 | 6-8 | 28-270 | 18.5 |

| F5YK1860-2P | 2 | 20 | 10.8 | 970 | 6-8 | 32-350 | 18.5 |

| F5YK1860-3P | 3 | 20 | 10.8 | 970 | 6-8 | 32-350 | 18.5 |

| F5YK1860-4P | 4 | 20 | 10.8 | 970 | 6-8 | 32-350 | 22 |

| F5YK2160-2P | 2 | 20 | 12.6 | 970 | 6-8 | 40-720 | 22 |

| F5YK2160-3P | 3 | 20 | 12.6 | 970 | 6-8 | 40-720 | 30 |

| F5YK2160-4P | 4 | 20 | 12.6 | 970 | 6-8 | 40-720 | 30 |

| P5YK2460-2P | 2 | 20 | 14.4 | 970 | 6-8 | 50-750 | 30 |

| P5YK2460-3P | 3 | 20 | 14.4 | 840 | 6-8 | 50-750 | 30 |

| P5YK2460-4P | 4 | 20 | 14.4 | 840 | 6-8 | 50-750 | 37 |

| P5YK2475-2P | 2 | 20 | 18 | 840 | 6-8 | 60-850 | 30 |

| P5YK2475-3P | 3 | 20 | 18 | 840 | 6-8 | 60-850 | 37 |

| P5YK2475-4P | 4 | 20 | 18 | 840 | 6-8 | 60-850 | 45 |

| P5YK3060-2P | 2 | 20 | 18 | 840 | 6-8 | 70-900 | 37 |

| P5YK3060-3P | 3 | 20 | 18 | 840 | 6-8 | 70-900 | 45 |

| P5YK3060-4P | 4 | 20 | 18 | 840 | 6-8 | 70-900 | 2x30 |

| F5YK3072-2P | 2 | 20 | 21.6 | 840 | 6-8 | 80-1080 | 37 |

| F5YK3072-3P | 3 | 20 | 21.6 | 840 | 6-8 | 80-1080 | 45 |

| F5YK3072-4P | 4 | 20 | 21.6 | 840 | 6-8 | 80-1080 | 45 |

| F5YK3080-2P | 2 | 20 | 24 | 840 | 6-8 | 84-1080 | 2x30 |

| F5YK3080-3P | 3 | 20 | 24 | 840 | 6-8 | 84-1080 | 2x37 |

| F5YK3080-4P | 4 | 20 | 24 | 840 | 6-8 | 84-1080 | 2x45 |

| F5YK3280-2P | 2 | 20 | 25.6 | 840 | 6-8 | 84-1080 | 2x30 |

| F5YK3280-3P | 3 | 20 | 25.6 | 840 | 6-8 | 100-1200 | 2x37 |

| F5YK3280-4P | 4 | 20 | 25.6 | 840 | 6-8 | 100-1200 | 2x45 |

| F5YK3680-2P | 2 | 20 | 28.8 | 800 | 8-10 | 149-1200 | 2x45 |

| F5YK3680-3P | 3 | 20 | 28.8 | 800 | 8-10 | 149-1620 | 2x45 |

| F5YK4095-2P | 2 | 20 | 38 | 800 | 8-10 | 200-1800 | 2x55 |

| F5YK4095-3P | 3 | 20 | 38 | 840 | 8-10 | 200-1800 | 2x75 |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)