- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

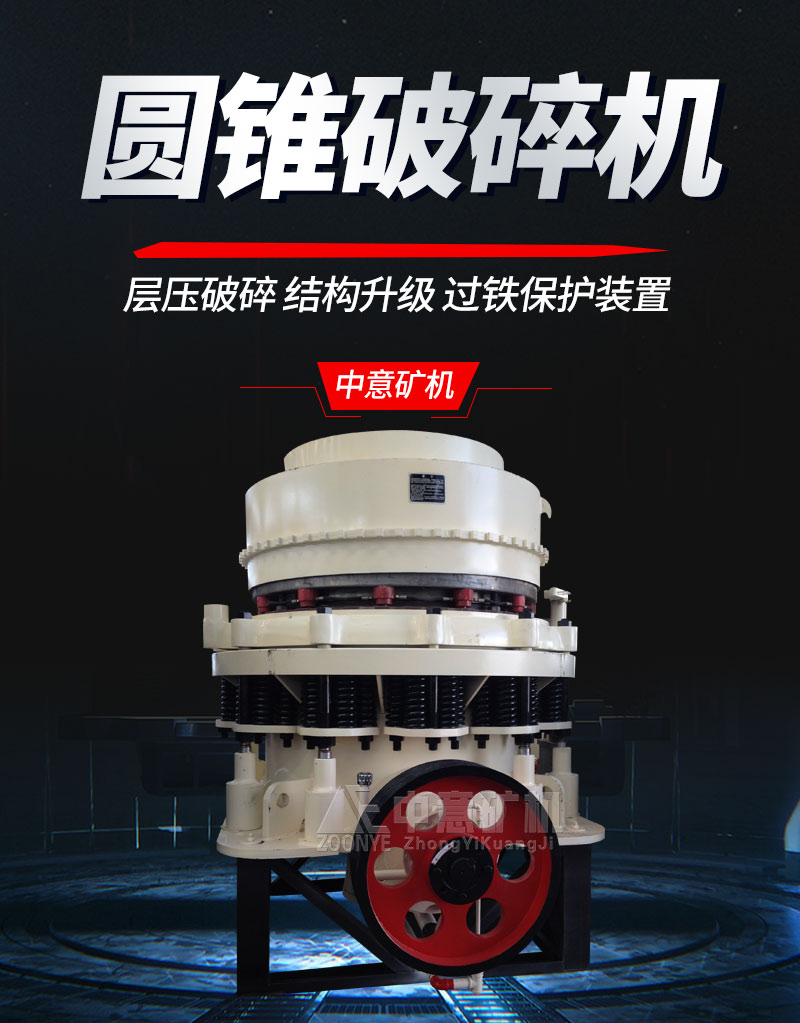

PSG Series Compound Cone Crusher

Processing Capacity:45-1941t/h

Feed Particle Size:≤391mm

Applicable Materials:River pebbles, limestone, dolomite, granite, diabase, basalt, gold ore, marble, fluorite ore, etc.

Application Scope:Construction stone crushing, metal ore crushing, cement, road construction, chemical energy and other fields.

- +8613503852957

- 7 * 24-hour Service Hotline

Ppring cone crusher

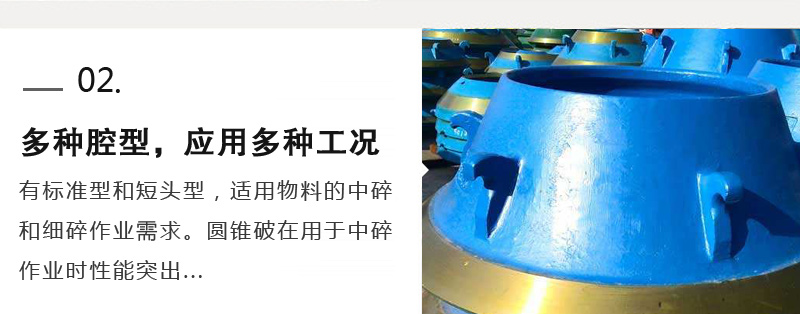

This series of crushers are suitable for crushing various ores and rocks with medium or higher hardness. It has the characteristics of reliable structure, high production efficiency, convenient adjustment, economical and practical. The spring safety system is an overload protection device that allows foreign iron blocks to pass through the crushing chamber without harming the machine. It uses dry oil or water seals to isolate the stone powder from lubrication to ensure reliable operation. This series of crushers are divided into three types: coarse crusher cone crusher, medium crushing cone crusher and tertiary crusher cone crusher. The standard type is suitable for medium crushing, the medium type is suitable for fine crushing, and the short head type is suitable for fine crushing. It can be purchased according to the different needs of users.

This process is for reference only. The specific process configuration needs to be determined based on the nature of the material, type of finished product, etc.

Suitable materials for spring cone crusher

Workshop composite cone crusher display pictures

Workshop composite cone crusher display pictures

High efficiency spring cone crusher

Simmons cone crusher production line

PSG Simons Crusher

Cone crusher

High efficiency cone crusher PSGB1313

Russian customers come to the factory for inspection

Cone crusher sent to Australian stone factory

As a type of mining equipment, spring cone crushers are generally used to crush hard rocks, ores, slag, refractory materials, etc. The degree of crushing and the particle size of the finished product can be adjusted by users according to their actual needs in order to create a better Good results.

Cameroon daily output of 3,000 cubic meters of sand and gravel production line

Malaysia’s limestone gravel production line with an annual output of 500,000 cubic meters

Henan Nanyang Fangcheng cobblestone crushing and sand making production line

Ballast production project of Zhengzhou Railway Bureau, Henan Province

Jaw crusher + cone crusher sand and stone production line sent to Xining, Qinghai

Sichuan Guang'an Expressway sand and gravel production line equipment

Advantages And Characteristics

High safety and low failure rate When foreign objects that are not easily broken or the equipment is overloaded in the crushing chamber, the spring safety device can automatically increase the discharge port to discharge the foreign objects to ensure safety performance. The product has good strength and high processing ability. It adopts the lamination crushing principle, which greatly reduces needle-shaped materials. The combination of high-performance crushing cavity and high crushing frequency greatly improves the processing capacity. Operation and maintenance are easy and complete. Coarse crushing, medium crushing and fine crushing. The structure is simple, easy to operate and maintain, the discharge port can be adjusted quickly, especially the liner is easy to replace quickly, reducing downtime. Greater processing capacity The cone crusher (cone crusher) combines a high-speed stroke, which increases the rated power and output of the cone crusher, greatly increasing the processing capacity of the equipment.

Working Principle

During operation, the cone crusher drive shaft and cone crusher cone are rotated by the rotation of the motor through the pulley or coupling, driven by the eccentric sleeve. Therefore, the broken wall of the crushing cone is close to the surface of the shackle wall fixed on the adjusting sleeve, so that the ore is continuously impacted, squeezed and bent in the crushing chamber, thereby achieving the crushing of the ore.

Technical Parameter

| Model | Cavity type | Stroke | Adjustment range of discharge port(mm) | Maximum feeding particle size(mm) | Processing power(t/h) | Power(kw) |

| PSG1200C-D | coarsely chopped | 22 | 19-50 | 180 | 110-250 | 132 |

| PSG1200S-X | finely chopped | 15 | 16-40 | 80 | 80-180 | |

| PSG1400C-D | coarsely chopped | 30 | 30-60 | 235 | 210-530 | 220 |

| PSG1400Z-D | medium broken | 30 | 25-50 | 215 | 200-500 | |

| PSG1400Z-X | medium broken | 25 | 22-45 | 180 | 180-475 | |

| PSG1400S-X | finely chopped | 25 | 19-40 | 100 | 130-260 | |

| PSG1650C-D | coarsely chopped | 34 | 35-65 | 300 | 280-610 | 250 |

| PSG1650Z-D | medium broken | 34 | 30-60 | 260 | 265-580 | |

| PSG1200Z-X | medium broken | 34 | 25-50 | 240 | 240-550 | |

| PSG1650S-X | finely chopped | 28 | 20-45 | 130 | 180-350 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)