- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

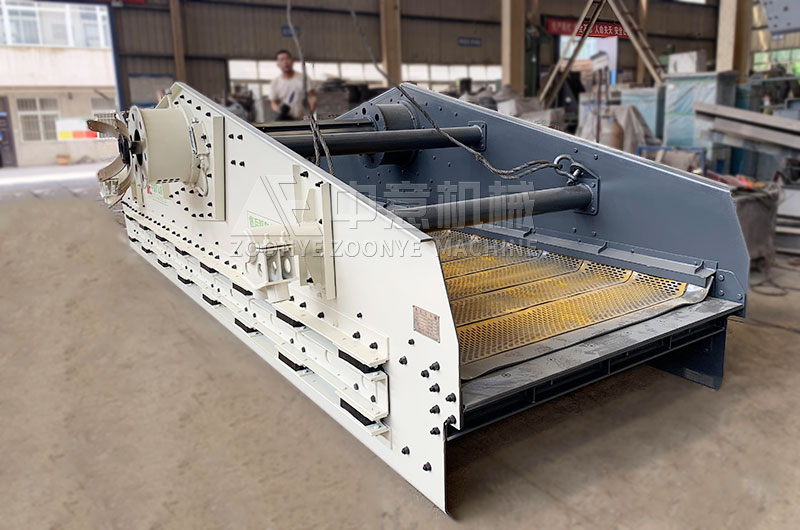

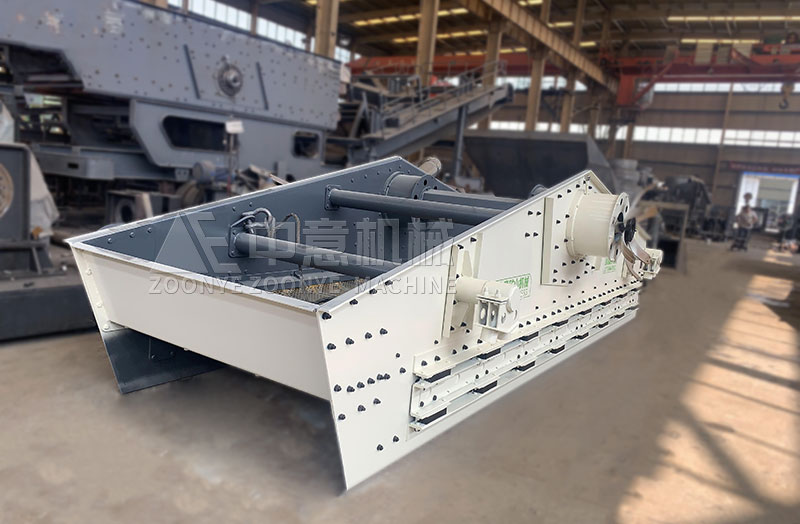

Flip-flow Screen

Processing Capacity:20-500m³/h

Feed Particle Size:≤50mm

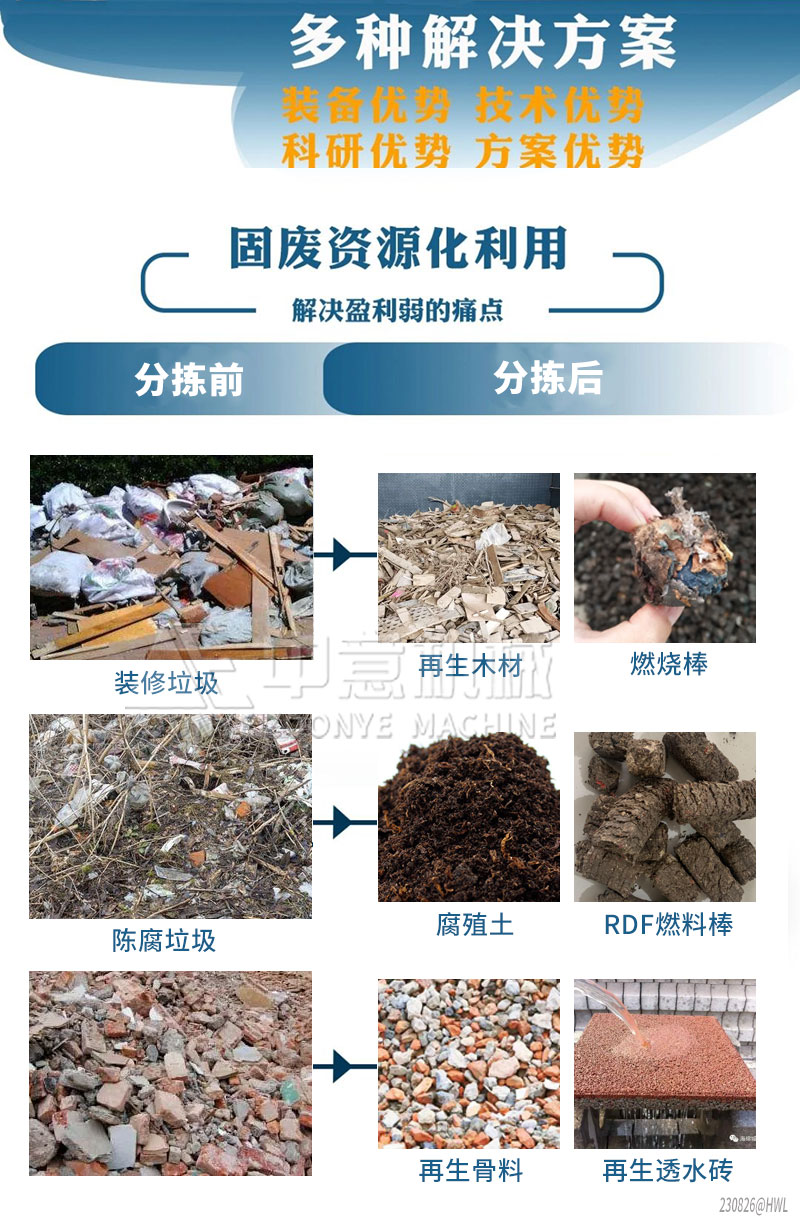

Applicable Materials:Solid waste such as decoration waste, old waste, construction waste, bulky waste, etc.

Application Scope:Construction and decoration industry, mining, chemical industry

- +8613503852957

- 7 * 24-hour Service Hotline

The flip-flow screen is a device specially designed for screening wet materials with high viscosity and high water content. The design principle of the relaxation screen is that a single drive generates dual vibrations, which effectively separates wet and sticky materials. Loose layers, layered and through screens can achieve very high screening efficiency with a relatively small screen area and ensure that the screen is not blocked.

Product Advantages

The flip-flow screen is designed with a polyurethane screen. The flip-flow screen can transmit 50g of acceleration to the material, allowing the material to be fully thrown and stratified. It has a self-cleaning function, and the processing capacity and screening efficiency are greatly improved. The whole machine is made of thickened steel plates. The fully anti-loosening bolt welded structure prevents the screen connection parts from loosening. The screen plate is installed by pressing in and prying out for easy maintenance. The oil level gauge can easily confirm whether the oil level in the tank is appropriate. No need to check it every day. Refuel and replace once every 3-6 months. The thin oil exciter is easier to start in low temperature environments. The soft connection automatically adjusts the concentricity and reduces impact loads. The universal coupling can protect the bearings and has the function of buffering and shock absorption. It is widely used. It is used for dry screening operations of medium-fine-grained, wet, sticky and other difficult-to-screen materials. It has the characteristics of not easy to block holes, good wear resistance, and high screening efficiency.

Solid Waste Resource Utilization

Working Principle

When the flip-flow screen is working, the screen mesh alternately tightens and relaxes, causing the material to produce forward bouncing motion, which can prevent the material from adhering to the screen mesh and blocking the screen holes. Through the exciter of the vibration device, the screen mesh begins to vibrate, causing the material to move Relative motion occurs on the screen. According to the size, it passes through different sieve holes. Larger particles will be blocked above the screen, while smaller particles fall through the sieve holes to the discharge port below. The screen can be adjusted as needed. Angle and vibration frequency to achieve the desired grading effect.

Real Shots From The Manufacturer

Flip-flow Screen

Solid Waste Treatment Equipment -Flip-flow Screen

Principle of Flip Screen Sorting

ZhongYi Flip-flow Screen

Technical Parameter

| Model | Power(kw) | Processing capacity(m³/h) | Feed particle size(mm) |

| ZKR1548 | 11 | 30~60 | ≤80 |

| ZKR1860 | 18.5 | 80~100 | ≤80 |

| ZKR2160 | 22 | 100~200 | ≤80 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)