- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

Bounce Screen Application Range

Processing Capacity:80-525t/h

Feed Particle Size:1000mm

Applicable Materials:Suitable for aggregate shaping, artificial sand making and high-grade highway aggregate production.

Application Scope:The product has excellent grain shape, in the form of a cube, with very low needle and flake content, and is suitable for aggregate shaping, artificial sand making and highway aggregate production.

- +8613503852957

- 7 * 24-hour Service Hotline

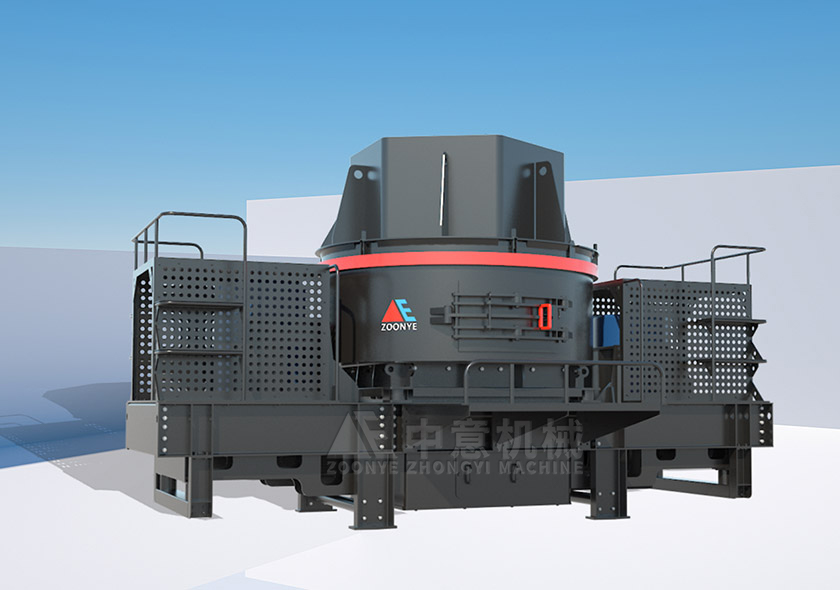

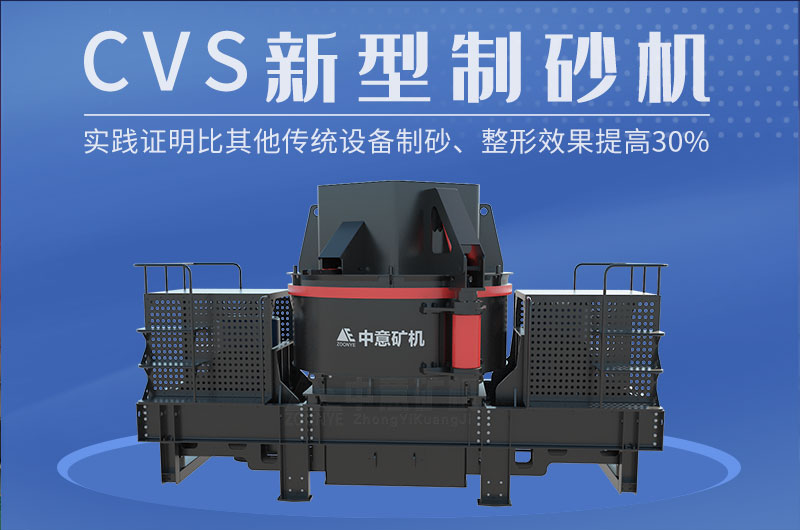

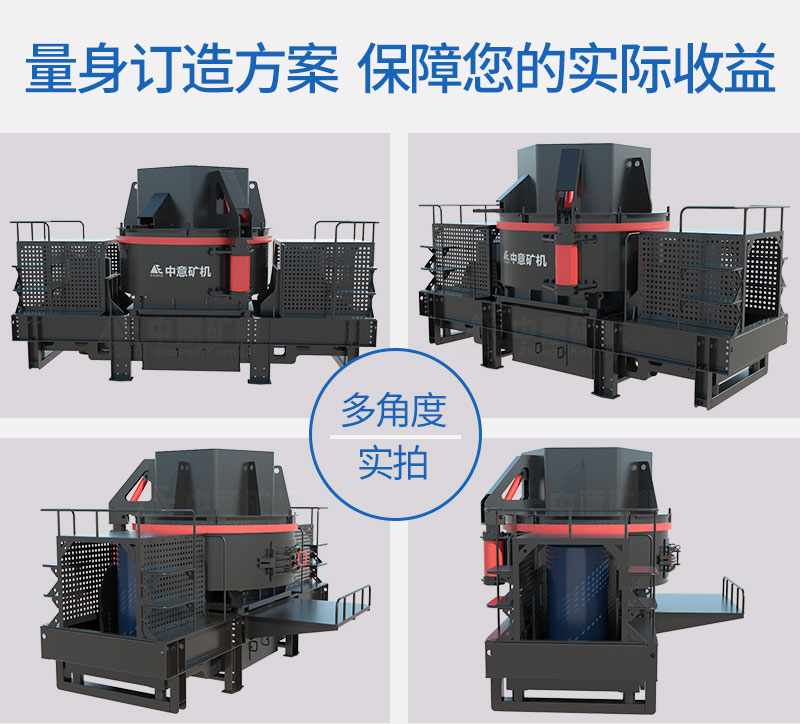

CV series new sand making machine, also known as sand making machine and sand blasting machine, is developed by our company by introducing the mature "rock on stone" and "stone on iron" crushing principles and technologies, combined with the actual situation of domestic sand making equipment production. Produced high-efficiency and high-efficiency gravel equipment with domestic and foreign standards. At present, fixed sand making machine models are mainly divided into three series: CV, VSI and PL.

Our company's sand making machine is widely used in the processing of various hard and brittle materials such as rocks (quartz, cobblestone, limestone, dolomite, granite, etc.), abrasives, refractory materials, cement clinker, iron ore, concrete aggregates, etc. Medium crushing and fine crushing (sand making), it is particularly suitable for processing and producing sand for construction and gravel for road construction.

Advantages And Characteristics

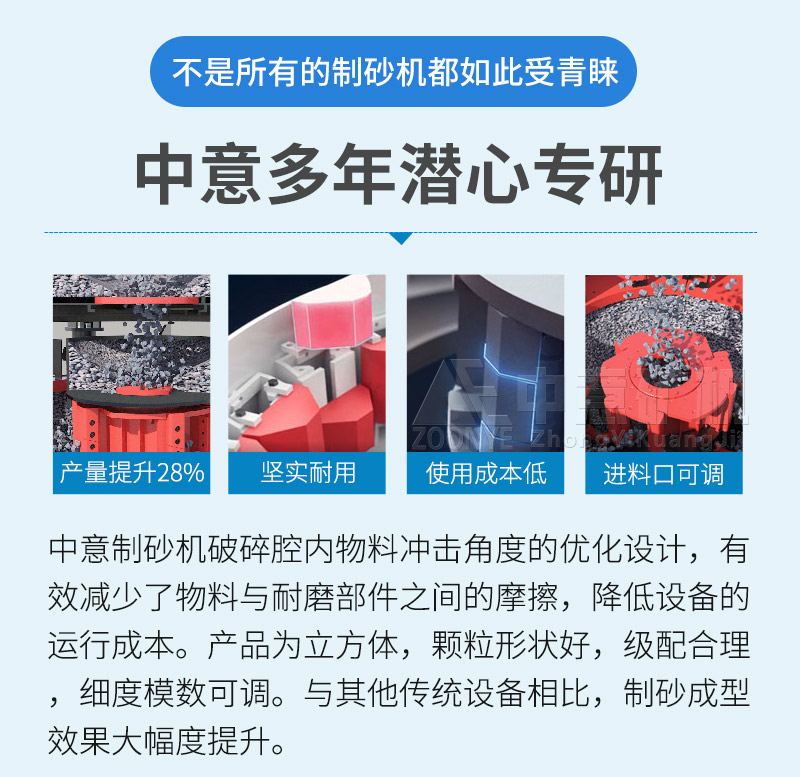

1. The crushing efficiency is higher, with fine crushing and coarse grinding functions;

2. The rotation speed is increased, the crushing ratio is larger, the deep-cavity rotor and the output are higher;

3. Simple structure, convenient installation and maintenance, and low operating cost;

4. Structural optimization, energy saving, low carbon and more environmentally friendly;

5. Thin oil lubrication, multiple protection measures to reduce downtime, high degree of automation and long service life;

6. The product has excellent grain shape, in the form of a cube, with very low needle and flake content, and is suitable for aggregate shaping, artificial sand making and highway aggregate production.

Working Principle

Working principle of CV sand making machine

The material falls into the feed hopper, enters the high-speed rotating rotor through the central feed hole, and is fully accelerated and thrown out through the launch port. It first collides with a part of the material that rebounds and falls freely, and then impacts together with the material in the surrounding vortex cavity. The vortex material lining (or impact block) is first rebounded to the top of the crushing cavity, and then deflected to move downward. It collides with the material emitted from the impeller flow channel to form a continuous material curtain, which is discharged through the lower discharge port.

Technical Parameter

| Model | Power(kw) | Throughput(t/h) |

| CV8620 | 200 | 80-130 |

| CV8622 | 220 | 90-140 |

| CV8625 | 250 | 100-150 |

| CV8628 | 280 | 120-180 |

| CV8640 | 200*2 | 150-200 |

| CV8644 | 220*2 | 180-250 |

| CV8650 | 250*2 | 200-300 |

| CV1132 | 160*2/315 | 180-260 |

| CV1140 | 200*2 | 240-330 |

| CV1144 | 220*2 | 250-360 |

| CV1150 | 250*2 | 300-420 |

| CV1163 | 315*2 | 400-525 |

Note: Stone on stone shaping - stone on iron sand making - open impeller can enter 100MM

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)