- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

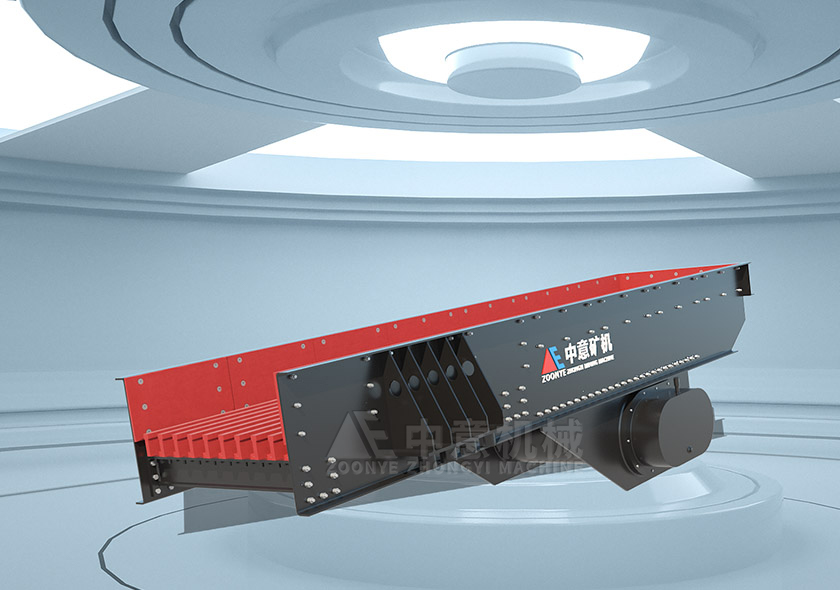

ZSW Vibrating Feeder

Processing Capacity:96-800t/h

Feed Particle Size:≤800mm

Applicable Materials:Production of all kinds of gravel and gravel....

Application Scope:It is used in combined crushing and screening equipment in sand and gravel plants, metallurgy, coal mines, mineral processing, building materials, chemicals, abrasives and other industries.

- +8613503852957

- 7 * 24-hour Service Hotline

ZSW series vibrating feeder is mainly used for continuous and uniform feeding of coarse crusher equipment, and can screen fine materials at the same time, which increases the functions of the crusher equipment. The body of the equipment adopts a vibrator device to ensure that the equipment can withstand the impact of cutting materials. In the entire production line process, 1 is conveyed to the feeder through the silo, and the raw material is evenly fed into the crusher equipment, thereby eliminating the crash site caused by uneven feeding. The crusher equipment has a sturdy grate bar and steel frame structure, which increases the life of the equipment and lays a solid foundation for longer-term operation in the future. This equipment is widely used in combined crushing and screening equipment in metallurgy, coal mines, mineral processing, building materials, chemicals, abrasives and other industries.

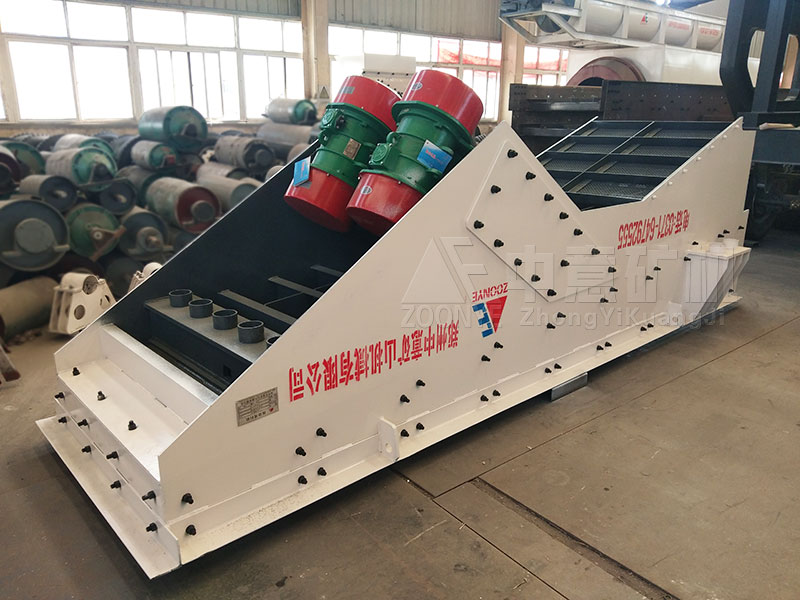

Real shots of feeder workshop

Feeder manufacturer

Large picture display of feeder

Vibrating feeder

Feeder

Zhongyi feeder

ZSW series vibrating feeder

ZSW feeder

Advantages And Characteristics

1. Linear motion trajectory and stable vibration;

2. Process design can prevent material clogging;

3. The gap between the bars can be adjusted humanely.

Working Principle

ZSW series vibrating feeder equipment consists of a feeding trough, vibrator equipment, spring base, and transmission auxiliary device. The exciter of the tank vibrating feeder and equipment is the core. The exciter is composed of two main and negative (mutual) gears. A motor drives the triangular belt to drive the driving shaft, where it rotates in agreement with the positive and negative gears, making the equipment base device Reverse rotation causes the tank body to vibrate, causing the material to flow continuously to achieve the purpose of conveying the material.

Technical Parameter

| Model | Maximum feed particle size(mm) | Processing power(t/h) | Motor Power(kw) |

| ZSW-380×95Ⅱ | 500 | 96-160 | 11 |

| ZSW-420×110 | 580 | 120-240 | 15 |

| ZSW-490×96 | 500 | 120-240 | 15 |

| ZSW-490×110Ⅱ | 630 | 120-280 | 15 |

| ZSW-590×110 | 630 | 150-350 | 22 |

| ZSW-600×130 | 750 | 400-560 | 22 |

| ZSW-600×150 | 800 | 460-575 | 30 |

| ZSW-600×180 | 800 | 600-800 | 37 |

| ZSW-600×200 | 800 | 600-800 | 45 |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)