- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

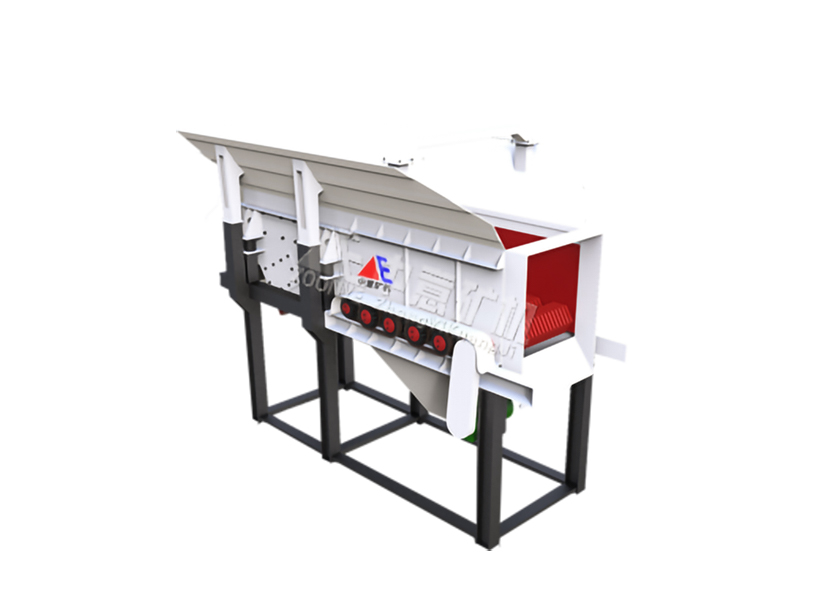

GDW Series Roller Screen Feeder

Processing Capacity:80-200t/h

Feed Particle Size:<800mm

Applicable Materials:Construction and decoration waste, river pebbles, limestone, cobbles and other materials

Application Scope:Coal, mining, sand and gravel, building materials, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

The GDW series roller screen feeder is a new type of feeding equipment. It has both feeding and screening functions. It is specially designed for continuous feeding of heavy crushers. After screening and removing mud, It reduces the burden on the crusher, avoids the chance of the crusher being blocked, improves production efficiency, and reduces energy consumption. The roller screen feeder is suitable for feeding and pre-screening of mud-containing materials. The screen holes are not easily blocked by wet materials. The feeding amount can be automatically adjusted according to the load of the crusher, which can give full play to the working efficiency of the crusher. Since this is a front-mounted screening, it can screen out the fine materials that already meet the requirements in the raw materials, so it not only improves the production capacity of the crushing system, but also reduces the wear and tear of the crusher. And because there are many muddy components in fine materials, screening them out can reduce the chance of the crusher being blocked by sticky wet materials.

Zhongyi Mining Machinery Roller Screen Feeder

Roller screen feeder

Roller feeder

Roller feeding equipment

Advantages And Characteristics

Advantages of roller screen feeder

1. After screening out the fine materials and mud that meet the requirements in the raw materials, the production capacity of the crushing system is improved, the wear of the crusher is reduced, and the work is more reliable.

2. The feeding amount can be automatically adjusted according to the load of the crusher, giving full play to the working efficiency of the crusher.

3. This machine is especially suitable for screening bulk materials. There is a mud removal device under the screening roller, and it is also capable of handling sticky and wet materials.

4. This machine has dual functions, does not occupy much space, does not increase equipment purchase costs, and is suitable for use with various ore and construction waste crushers.

5. Pre-screening can screen out the fine materials that meet the requirements in the raw materials, which not only improves the production capacity of the crushing system, but also reduces the wear and tear of the crusher.

6. It is suitable for feeding and pre-screening operations of mud-containing materials. The screen holes are not easily blocked by wet materials. The feeding amount can be automatically adjusted according to the load of the crusher to give full play to the working efficiency of the crusher.

GDW series roller screen feeder price analysis

Real shot of roller screen feeder

There are many models of roller screen feeders on the market. Due to the configuration of equipment with different specifications and models, and the selection of manufacturers with different scales and strengths, the price of a roller screen feeder is also different. Zhongyi Mining Machinery is a powerful manufacturer. The equipment it produces is sold directly to customers, skipping multi-level intermediate agents. The equipment pricing is scientific and reasonable. For detailed quotations of roller screen feeders, you can consult online. Zhongyi Mining Machinery will Arrange professional technicians to provide you with a detailed quotation.

Working Principle

The GDW series roller screen feeder is composed of a feeder and a roller screen. The exciter of the tank vibrating feeder equipment is the core. The exciter consists of two main and negative (mutual) gears, with an electric motor. The V-belt is driven to drive the driving shaft, which rotates in agreement with the positive and negative gears, causing the equipment base device to rotate in reverse, and the tank body to vibrate, making the material flow continuously and evenly sending the material to the roller screen. The rotating shaft is driven and rotated by the driving equipment. , after the material enters the equipment, the material larger than the gap of the screen plate is transported from the top of the screen plate to the next process, and the material smaller than the gap of the screen plate falls from the gap to the collection belt below, and is transported out of the equipment by the collection belt.

Technical Parameter

| Model | Feeder model | Feeder power | Screening form | Screening power | Equipped with counterattack model |

| GDW09-1A | GZGT0924 | 2.2KW×2 | roller screening0920 | BWD-B5-17-7.5KW | PFW0810 |

| GDW10-1A | GZGT1024 | 3KW×2 | roller screening1020 | BWD-B5-17-7.5KW | PFW1310 |

| GDW13-1A | GZGT1324 | 3.7KW×2 | roller screening1420 | BWD-B5-17-7.5KW | PFW1314 |

| GDW15-1A | GZGT1524 | 3.7KW×2 | roller screening1620 | BWD-B5-17-7.5KW | PFW1315 |

| GDW09-1B | GZGT0924 | 2.2KW×2 | Vibrating rod screening | 4KW | PFW0810 |

| GDW10-1B | GZGT1024 | 3KW×2 | Vibrating rod screening | 4KW | PFW1310 |

| GDW13-1B | GZGT1324 | 3.7KW×2 | Vibrating rod screening | 5KW | PFW1314 |

| GDW15-1B | GZGT1524 | 3.7KW×2 | Vibrating rod screening | 5KW | PFW1315 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)