- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

LDYZ Crawler Mobile Cone Crusher

Processing Capacity:50-300t/h

Feed Particle Size:150-312mm

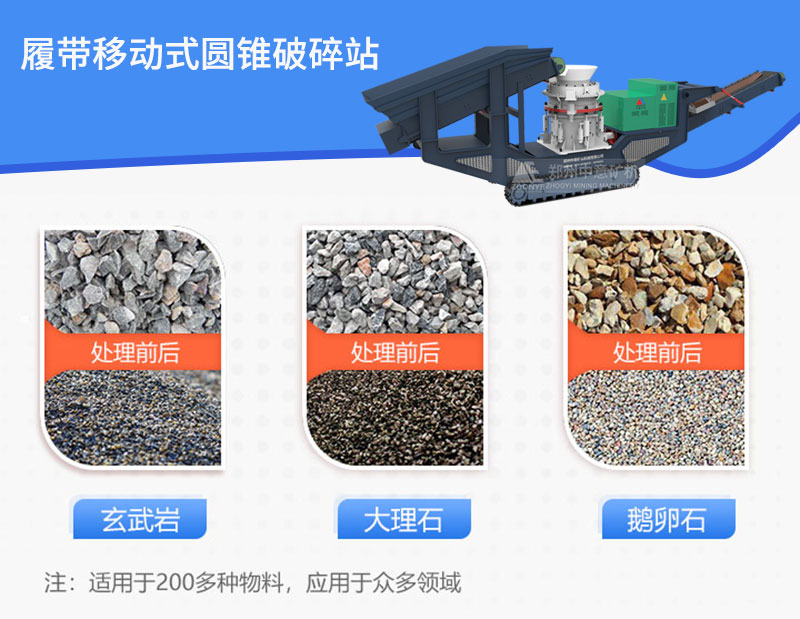

Applicable Materials:Coarse and fine crushing of hard materials with compressive strength not exceeding 150Mpa.

Application Scope:It is widely used in mining, water conservancy, transportation, railway, cement, building materials, metallurgy, chemical industry, electric power, construction and other industries.

- +8613503852957

- 7 * 24-hour Service Hotline

Crawler cone crushing station

The crawler cone crusher equipment innovatively manufactured by our company is mainly suitable for the utilization of different stone recycling resources. Through the feeder equipment, the raw materials are fed into the crusher, and the cone crusher and special vibrating screening equipment are used for continuous environmental protection and effective For operations, the application of screening equipment can also be eliminated according to customer needs. This set of equipment can also be assembled with other auxiliary equipment, which is fully flexible and convenient.

Crawler crushing and screening process

Crawler cone crushing station

Mobile cone crusher

Crawler cone crushing station

Crawler cone mobile crushing and screening of stones and other raw materials

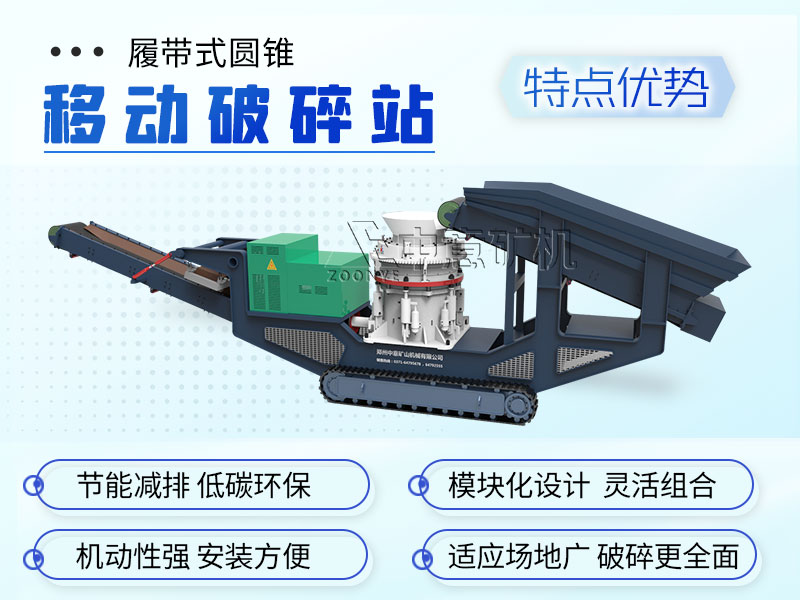

Advantages And Characteristics

1. It can be used as a separate crushing unit or constitute a multi-stage operation.

2. Crawler walking does not damage the road surface.

3. High crushing output and easy adjustment.

4. The ship-shaped structure is beautiful and the crushing efficiency is impressive.

5. Don’t be afraid of difficult circumstances and still work as before.

Working Principle

The overall structure is formed by a combination of different objects, including feeders, cone crushers, screening equipment and conveying equipment. It starts with the body chassis and uses a crawler-type drive chassis to move freely. Used to complete medium and fine crushing operations, this equipment can be configured with different types of cone crushers according to provincial needs and output requirements to form high-yield, low-consumption, high-quality recycled aggregates. During the crushing process, the station can rely on external power to drive the host equipment and auxiliary equipment/diesel generator set. The two options reflect the humanized thinking of equipment manufacturing. The raw materials enter the crushing cavity, are evenly fed by the feeder, and are fully crushed in the crusher. The produced medium and fine aggregates arrive at the new material warehouse with the conveyor belt, and those that do not meet the standards are returned for crushing again, thereby ensuring the particle size of the aggregates. uniform shape and excellent quality.

Technical Parameter

| Name | Raw materials warehouse | Belt feeder | Cone crusher | Ship type steel frame | Track assembly | Diesel engine unit (Weichai) | Hydraulic assembly | Electrical assembly | Steel structural parts | Belt conveyor (discharging) | Hydraulic legs | Power (KW) |

| LDYZ900 | LDYDS | B800=6.8m | PSGB0918 | LDYDS | LDYDS-20T | 50GF-C-D | LDYDS | LDYDS | LDYDS | B800=10m | YDS50 | 93.5 |

| LDYZ1300 | LDYDS | B1000=6.8m | PSGB1324 | LDYDS | LDYDS-26T | 145GF-C-D | LDYDS | LDYDS | LDYDS | B1000=11m | YDS50 | 178.5 |

| LDYZ1600 | LDYDS | B1200=6.8m | PSGB1600 | LDYDS | LDYDS-40T | 145GF-C-D | LDYDS | LDYDS | LDYDS | B1200=12m | YDS50 | 276 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)