- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

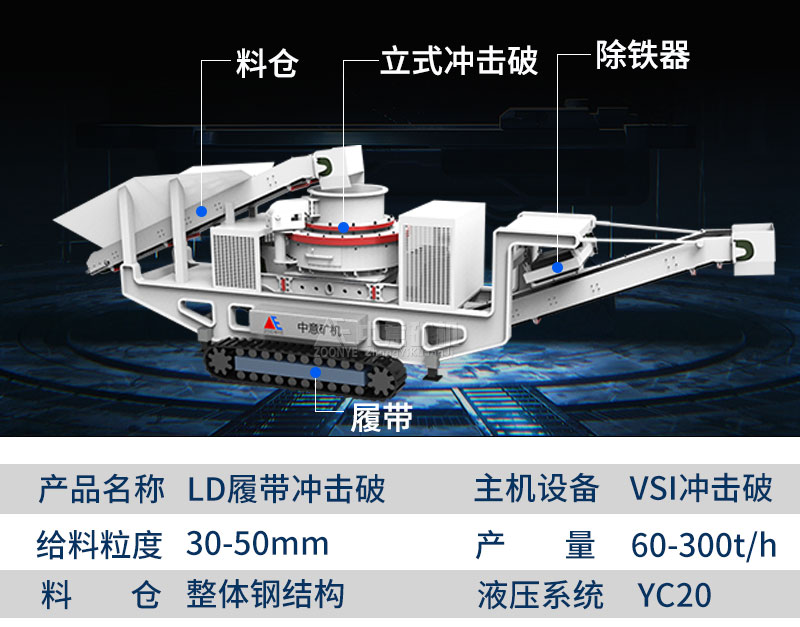

LD Crawler Mobile Impact Crusher

Processing Capacity:60-300t/h

Feed Particle Size:≤700mm

Applicable Materials:Granite, basalt, limestone, pebbles, bluestone, sandstone, brown corundum...

Application Scope:Sand and gravel mixing station, refractory material production, sand and gravel for high-speed rail and highway construction...

- +8613503852957

- 7 * 24-hour Service Hotline

Crawler sand making machine equipment manufacturer, professional manufacturer

The crawler impact crusher is widely used for medium and fine crushing (sand making) of various hard and brittle materials such as rocks, cement clinker, quartz stone, iron ore, abrasives, refractory materials, concrete aggregates, etc. Construction sand, highway water stabilization layer (an important component). The mobile impact crusher has a simple structure, low price, smooth operation, high efficiency and energy saving, and the impeller and vortex crushing chamber have automatic adjustment functions, which further reduces the wear and tear of the equipment and the maintenance workload. The mobile impact crusher equipment has mobile "crawler shoes" and has a lot of experience in pollution suppression. The overall equipment forms a closed loop, making the equipment more compact and smooth.

履Belt type mobile impact crusher uses

Advantages And Characteristics

1. Accessories design and complete process plan.

2. Simple operation and good discharging.

3. Safety, environmental protection, and intelligent diversification.

4. Strong tolerance, strong and wear-resistant.

5. The product is cube-shaped and has little iron pollution.

6. Remote control operation, intelligent operation, saving labor costs.

Working Principle

Remarks: This process plan is for reference only. The specific solution needs to be determined based on the size of the raw materials, type of discharge, material hardness, etc.

The material enters the crusher from the feed hopper, and is divided into two parts through the powder machine. One part of the powder machine equipment enters high-speed operation and accelerates rapidly in the impeller on the other side. The speed is so fast that through the pulse impact type The operation breaks the materials, and the materials change the direction of movement through the rebound lining plate. Through the movement, they hit the crusher multiple times, causing the aggregates to be born in the process of friction, impact, grinding, and dressing. The crushed aggregates are conveyed through The designated material warehouse of the machine equipment forms a closed loop with the circulating screening device.

Technical Parameter

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)