- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

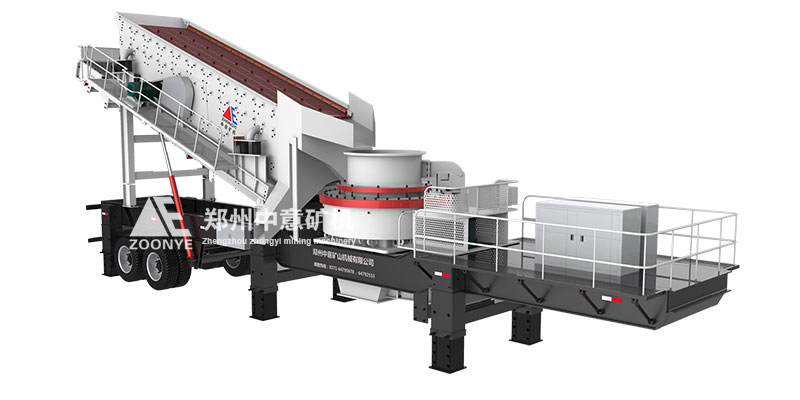

YDLS Tire Type Vertical Crushing Mobile Screening Station

Processing Capacity:80-300t/h

Feed Particle Size:45-55mm

Applicable Materials:Artificial sand making from river pebbles, mountain rocks (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, and stone chips.

Application Scope:Recycling of mines, coal mines, tailings and construction waste, earthworks, urban infrastructure, roads or construction sites and other site operations

- +8613503852957

- 7 * 24-hour Service Hotline

Mobile sand making machine

Mobile gravel production line configuration plan

Professional stone crushing equipment

Mobile sand making production line

The YDLS tire-type vertical crushing mobile screening station is an all-in-one sand making, crushing and screening equipment that is composed of a vibrating screen, a belt conveyor, a special sand making machine, an electric cabinet and a control box. It uses high-efficiency sand making equipment. The materials produced through high-quality and efficient processing of raw materials are also quite beautiful. The Zhongyi mobile sand making machine equipment has fast processing efficiency and high recovery rate. The key is that the cost is relatively low and the customers are considered realistically.

Mobile sand making machine

Mobile sand making equipment

Advantages And Characteristics

1. Vehicle-mounted feeder, vibrating screen, and belt conveyor.

2. The process technology and components are excellent and guaranteed.

3. Stable mobile performance and quick and convenient on-site installation of the equipment.

4. Integrated installation of motor and control box.

5. Excellent sealing performance and pollution-free production.

Working Principle

Mobile sand blasting machine equipment

During the operation of the tire-type vertical crushing mobile screening station, various feeding, crushing, and screening equipment work in coordination. The raw materials enter the crushing equipment for crushing processing. During this period, the aggregates are crushed into regular and highly transparent shapes. Strong granular recycled aggregates enter the special screening machine equipment after sand making. The qualified aggregates are discharged through the discharge port, and the aggregates that do not meet customer requirements enter the crusher again, thus forming a closed loop effect. Throughout the production process, the self-propelled mobile body design is used, which greatly improves the safety, effectiveness and on-site adaptability of the equipment.

Technical Parameter

| Model | YDLS0815 | YDLS9518 | YDLS1121 |

| Vibrating screen | 3YA1548 | 3YA1860 | 3YK2160 |

| vertical impact crusher | VSI8516/20 | VSI9526/28 | VSI1028/32 |

| Maximum feed particle size(mm) | 45 | 50 | 55 |

| Throughput(t/h) | 80-150 | 120-250 | 180-300 |

| Discharging belt conveyor under screen | B650 | B800 | B1200 |

| Hydraulic system | YZ20 | YZ20 | YZ30 |

| Total power(kw) | 186.5 | 287 | 372.5 |

| Frame configuration | 两桥 | 两桥 | 两桥 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)