- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

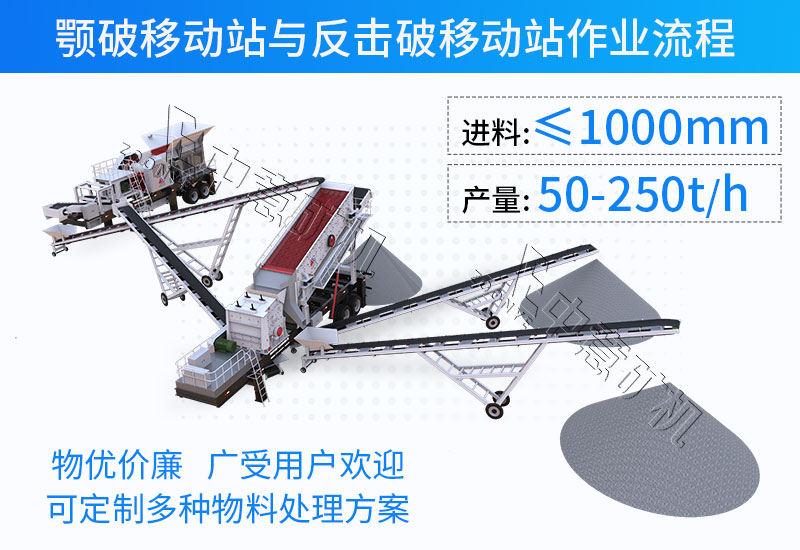

YDS Tire Type Jaw Crusher Mobile Crushing Station

Processing Capacity:40-320t/h

Feed Particle Size:≤750mm

Applicable Materials:Construction waste, rocks, various ores, concrete and other materials...

Application Scope:Suitable for various quarries and screening construction and demolition waste, mining operations, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

Jaw crusher mobile crushing station, expert in coarse crushing, sturdy and durable

YDS tire-type jaw crusher mobile crushing station is currently an integrated crushing and processing equipment commonly used in mining, construction waste treatment/decoration waste treatment, urban infrastructure and other fields. Its significant advantages are flexibility, lightness, strong mobility, and can be directly Going deep into the work site, the efficiency is also very high while ensuring quality. Such a mobile crushing station will not only create benefits, but also save a lot of costs during transportation. Mobile jaw crushers come in various combinations, generally consisting of jaw crushers, vibrating feeders, screening equipment, conveying equipment and other auxiliary crushing equipment. They have compact structure, reliable performance, high quality and low price, and are widely used. Popular with users.

Mobile jaw crushing station crushes many types of materials

The mobile jaw crushing station ordered by Guangdong Zhuhai Stone Factory is ready to go

Zhengzhou Zhongyi Mining Machinery’s new 750*1060 jaw crusher mobile crushing station is sent to Jiangsu Nanjing Sand and Gravel Plant

Advantages And Characteristics

1. Adaptable host device switching to meet customers’ individual needs.

2. Adopting a ship-shaped steel frame structure, the car body has a low chassis, is light in weight, and the volume is reasonably controlled.

3. Unit integration. It can be operated directly, eliminating tedious infrastructure installation and man-hour consumption.

4. Flexible parking function to quickly enter working mode.

5. Large crushing ratio, powerful crushing efficiency, and high-quality crushing effect.

Working Principle

When the tire-type mobile jaw crusher is in operation, the materials are fed into the jaw crusher through a special feeding device for coarse crushing, and then pass through a special circular vibrating screen to form a closed-circuit system. During this period, the dust is suppressed as much as possible. After being processed and screened, the qualified aggregates enter the second crushing process, while the unqualified aggregates are returned along the original route of the conveyor belt and crushed again. Qualified materials pass through the two-stage crushing process system and then enter the special screening machine equipment again. During the entire crushing process, the feeder equipment is specially designed to feed materials. It can screen out the fine sand in the raw materials in advance, and then through crushing and screening The system is divided into separate systems until the processing is qualified, and the qualified finished aggregate is transferred to the designated finished product warehouse through conveying equipment.

Technical Parameter

| Name | Raw materials warehouse | Vibrating feeder | Jaw crusher | Jaw crusher steel frame | mobile frame | Steel structural parts | Belt conveyor (discharging) | Belt Conveyor (Unearthed) | Electric control cabinet | Cable | Outrigger | Hydraulic system | Total power (KW) |

| YDS50 | YDS50 | GZT0724 | PE400×600 | PE400×600 | (两轴)11m | YDS50 | B650=8m | B500=3m | YDS50 | YDS50 | B500=3.2m | YDS50 | 48 |

| YDS80 | YDS80 | GZT0724 | PE500×75 | PE500×75 | (两轴)11m | YDS80 | B650=8m | B500=3m | YDS80 | YDS80 | B500=3.2m | YDS80 | 73 |

| YDS100 | YDS100 | GZT0932 | PE600×900 | PE600×900 | (两轴)11m | YDS100 | B800=8m | B500=3m | YDS100 | YDS100 | B650=3.2m | YDS100 | 78 |

| YDS180 | YDS180 | GZT1148 | PE750×1060 | PE750×1060 | (两轴)13m | YDS180 | B1000=8m | B500=3m | YDS180 | YDS180 | B500=3.2m | YDS180 | 145.5 |

| YDS300 | YDS180 | GZT1256 | PE900×1200 | PE900×1200 | (两轴)15m | YDS220 | B1200=8m | B500=3m | YDS220 | YDS220 | B650=3.2m | YDS220 | 201.5 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)