- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

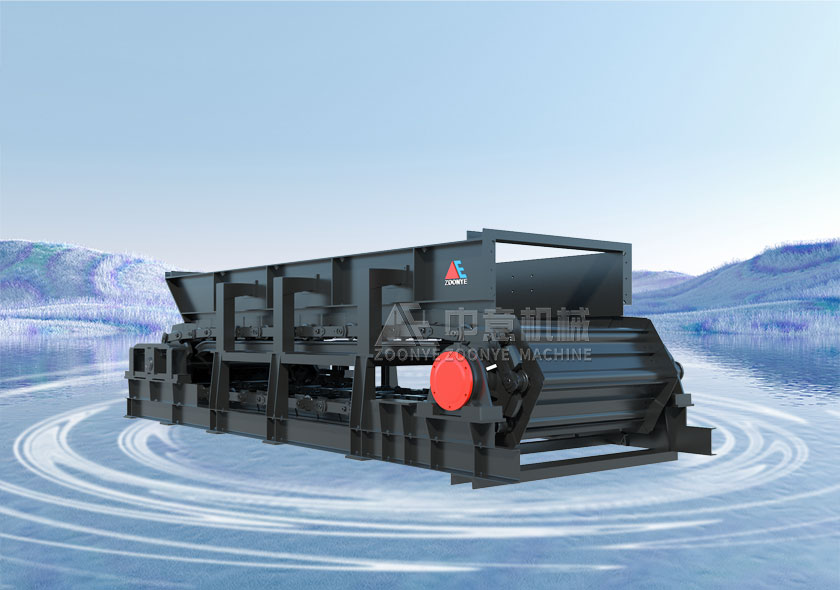

BW Heavy Duty Chain Plate Feeder

Processing Capacity:60-750m³/h

Feed Particle Size:≤1000mm

Applicable Materials:Ore, Coal, Construction Waste, etc...

Application Scope:Mining, Metallurgy, Coal, Building Materials, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

Heavy Duty Plate Chain Feeder

The BW heavy-duty chain plate feeder is a conveying equipment that uses a special metal chain plate as a load-bearing component. The equipment has strong adaptability and large conveying capacity. It can convey fine materials with a particle size of less than 5mm and can also convey more than 1m. of bulk materials. As a silo that continuously and evenly feeds materials to the primary crusher, the chain plate feeder can also be used to transport materials with larger particle sizes and specific gravity over short distances. The heavy-duty apron feeder can be installed horizontally or tilted.

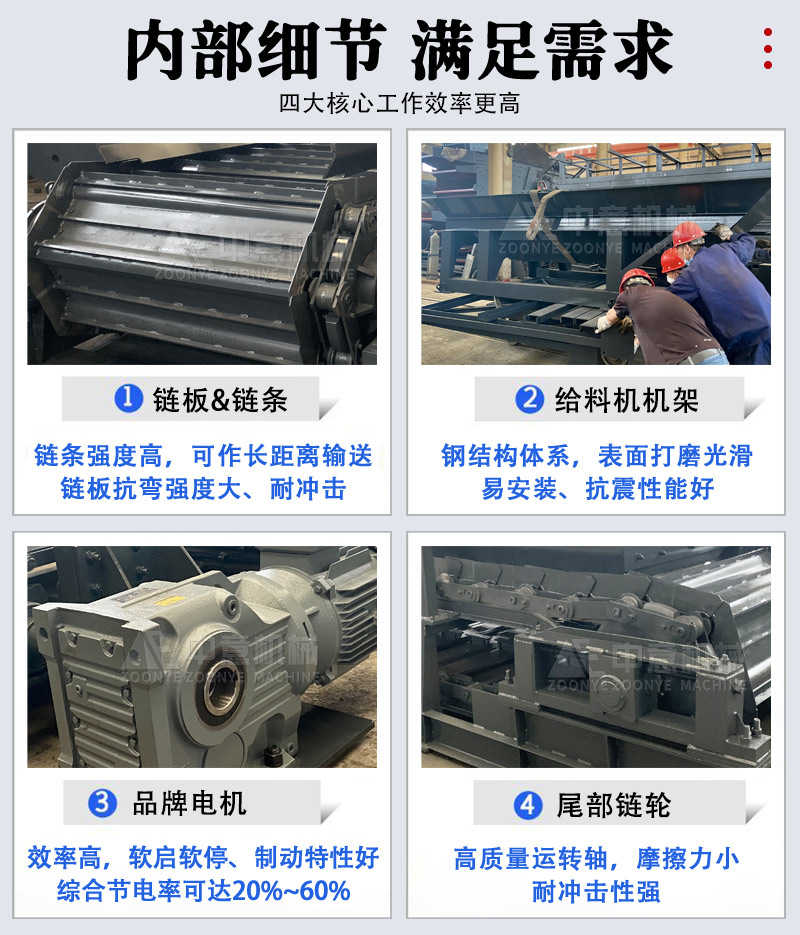

Product advantages

Plate Conveyor

1. The scale plate is stamped and formed from wear-resistant steel, which has good rigidity, strong impact resistance and strong impact resistance.

2. The whole machine has a compact structure, is easy to install and debug, has few wearing parts and is easy to replace.

3. Using chains as traction elements has the characteristics of high strength, high efficiency and reliable operation, and can realize short-distance transportation and long-distance transportation.

4. The crawler-type power transmission method uses rolling friction instead of sliding friction, which effectively reduces the driving power and chain traction; it has low running resistance, low power consumption, small wear, smooth operation, reliable operation and long service life.

5. It can realize short-distance transportation and long-distance transportation; it can be installed horizontally or tilted, with a maximum inclination angle of 20°.

Zhongyi Chain Conveyor Manufacturer

Chain Feeder

Working Principle

The BW heavy-duty chain plate feeder uses two endless flexible plate chains as traction parts. It is equipped with a chain plate carrying materials, which rotates circularly on the guide rail. The material enters from the driven end and is sent out from the active end. The electric motor is driven by a belt through a reducer and coupling to drive the driving sprocket to rotate. The driving sprocket drags the chain to move. The chain is connected to the chain plate for loading materials. The chain and chain plate are supported by upper and lower guide rails. The feed end is a driven sprocket that redirects the chain. The driven sprocket is mounted on the slide rail, and the chain can be tightened by adjusting the slide rail.

Technical Parameter

| Mmodel | Power(kw) | Feeding Quantity(m³/h) |

| QBL0840Chain Plate | 11 | 60-150 |

| QBL1040Chain Plate | 15 | 80-200 |

| QBL1240Chain Plate | 15 | 100-300 |

| BW1040Board Feeding | 18.5-22 | 60-250 |

| BW1240Board Feeding | 22-55 | 80-350 |

| BW1440Board Feeding | 22-55 | 100-450 |

| BW1840Board Feeding | 22-55 | 150-600 |

| BW1850Board Feeding | 22-75 | 100-350 |

| BW2050Board Feeding | 30-90 | 150-550 |

| BW2250Board Feeding | 37-110 | 200-650 |

| BW2450Board Feeding | 37-110 | 260-750 |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)