- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

MP Multi-cylinder Hydraulic Cone Crusher

Processing Capacity:495-2420t/h

Feed Particle Size:≤414mm

Applicable Materials:River pebbles, weathered sand, weathered stone, zircon sand, quartz sand, quartz stone, yellow sand, sand, quicklime, etc.

Application Scope:Suitable for medium and fine crushing of materials in mining, cement, sand and gravel, metallurgy and other industries

- +8613503852957

- 7 * 24-hour Service Hotline

MP multi-cylinder hydraulic cone

With the advancement of my country's infrastructure project construction and the accelerated pace of mining, crushers are increasingly used in various ore and rock crushing processes. The crushing of hard materials also places higher and higher requirements on the performance and discharge quality of the crusher itself. Come higher and higher. In order to solve the problems of poor particle shape, low efficiency and high wear when the cone crusher crushes hard and difficult-to-break materials. Zhongyi Mining Machinery's MP series multi-cylinder hydraulic cone crusher breaks through the previous structural design concept of cone crushers. It adopts a structure in which the main shaft is fixed and the eccentric sleeve rotates around the main shaft. It is successfully developed by Zhongyi Mining Machinery based on years of experience in crusher research and development and combined with foreign technology. A new generation of high-efficiency cone crusher.

MP multi-cylinder hydraulic cone crusher can process materials

Advantages And Characteristics

1. Higher output and efficiency, improving the competitiveness of enterprises

The Zhongyi MP series multi-cylinder hydraulic cone crusher has a compact and sturdy structure, and can increase the crushing output by more than twice compared with competitors' products. The optimized design of the MP series incorporates the latest process technology to produce high crushing force. With proven experience in harsh mining operating conditions, MP can achieve higher output at the same discharge particle size or finer discharge product particle size at the same output compared with other equipment.

2. Simple operation

The push-button control device makes the operation of MP multi-cylinder hydraulic cone crusher very simple. A hydraulic motor further adjusts the discharge opening to compensate for wear. The control system can also be used for remote control adjustment. Whether discharge opening adjustments are performed manually by the operator or automatically by the control system, the new "breaking force" sensor provides an indication of safe operation.

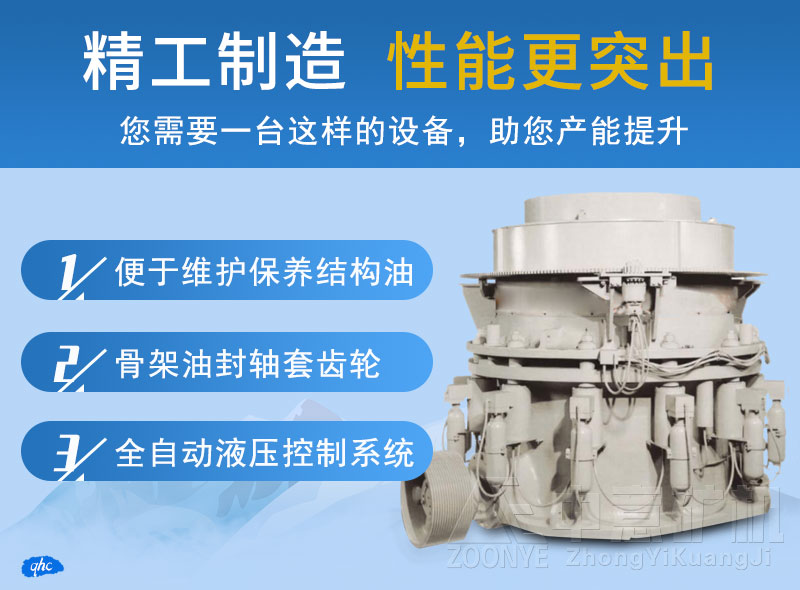

3. Convenient maintenance

The MP series features push-button disassembly and maintenance. Modular components can be easily replaced if necessary. The entire crusher uses highly wear-resistant bronze bushings to ensure load capacity in harsh crushing operating environments. The proven cone liner "wedge" retention system provides a safe and simple method of liner retention and makes liner changes more convenient and efficient.

4. Laminated crushing and good discharge particle shape

The MP series uses the lamination crushing principle to crush materials. By optimizing the equipment and cavity type, the lamination crushing efficiency is improved. The crushing efficiency is high, the wear of wearing parts is low, the finished grain shape is cubic, and the fine particle content is high, improving Improve the quality of finished products and reduce the production costs of equipment and the entire system.

5. Made of high wear-resistant materials, long service life

The multi-cylinder hydraulic cone crusher uses high-quality new alloy materials. The manufacturing process is strict and mature. Every process is meticulous to ensure that the equipment leaves the factory in good condition and of high quality, which greatly extends the service life of the equipment and allows users to invest. Small, huge benefits.

Working Principle

When the MP multi-cylinder hydraulic cone crusher is working, the rotation of the motor drives the pulley or coupling, the transmission shaft and the cone part to make the eccentric shaft perform periodic swing motion under the axis center line. When the MP multi-cylinder hydraulic cone crusher works, the moving cone moves along the inner surface When the machine performs a rotating pendulum motion and is close to the fixed cone, the material is squeezed and bent by the moving cone and is broken. The hydraulic safety system can eliminate the faults of the support sleeve and the fixed cone part through hydraulic pressure when the machine has an iron failure or a boring phenomenon. It plays a very good insurance role, and at the same time greatly reduces the maintenance rate and improves production efficiency.

Technical Parameter

| Model | Cavity type | Tight edge feeding port A | Tight edge feeding port B | Tight edge feeding port C | Production capacity of tight edge discharge port | Overall dimensions(mm) | ||||

| 13 | 19 | 25 | 38 | 50 | ||||||

| MP800 | Short head and thin type | 40 | 91 | 6 | 495-585 | 580-690 | 735-980 | 1100-1285 | 1460-1935 | 2195×1158×1651 |

| short head medium | 68 | 117 | 6 | |||||||

| Short head thick type | 113 | 162 | 12 | |||||||

| Standard ultra-slim type | 144 | 193 | 19 | |||||||

| Standard slim type | 241 | 282 | 19 | |||||||

| Standard medium size | 308 | 347 | 25 | |||||||

| Standard thick type | 343 | 384 | 32 | |||||||

| MP1000 | Short head and thin type | 64 | 128 | 8 | 615-730 | 720-900 | 950-1210 | 1375-1750 | 1830-2420 | 2195×1158×1651 |

| short head medium | 104 | 169 | 10 | |||||||

| Short head thick type | 140 | 203 | 10 | |||||||

| Standard ultra-slim type | 241 | 295 | 22 | |||||||

| Standard slim type | 242 | 300 | 25 | |||||||

| Standard medium size | 343 | 390 | 32 | |||||||

| Standard thick type | 360 | 414 | 38 | |||||||

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)