- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

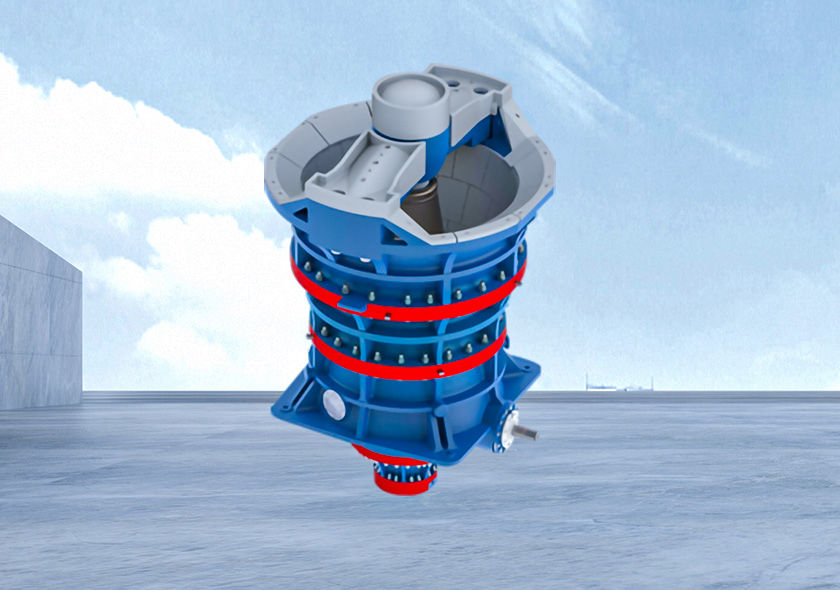

XHZ Gyratory Crusher

Processing Capacity:5250-8750t/h

Feed Particle Size:≤1575mm

Applicable Materials:Quartz stone, granite, river pebbles, cobblestones, limestone, dolomite, iron ore, concrete, coal, gypsum, etc.

Application Scope:It is widely used in ore crushing, railways, highways, large-scale water conservancy and hydropower, construction projects, machine-made sand production, dry mortar, concrete mixing stations, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

中意旋回破碎机

XHZ gyratory crusher is a large-capacity, intelligent new coarse crushing equipment designed by Zhongyi Mining Machinery using international crushing technology and optimized design. It is suitable for coarse crushing of various types in metallurgy, building materials, chemical industry, hydropower and other industries. The hardness of an ore or rock.

Zhongyi XHZ gyratory crusher can provide more efficient production capacity and ideal finished product particle shape than cone crusher, and the equipment is automated and easy to automatically control. In terms of equipment flexibility and reliability, it can directly create more for customers. high yield. This large-scale equipment is easy to maintain and maintain, and its performance is stable. It is a new generation of large-scale crushing machinery and equipment in today's mining and construction industry. Its new features can significantly reduce the investment cost in the coarse crushing section from the mining operation surface to the coarse crushing pile.

Application of gyratory crusher

Gyratory crusher is a typical coarse crushing equipment in large mineral processing plants. Both the gyratory crusher and the jaw crusher can be used as coarse crushing crushing machinery. Compared with the two, the advantage of the gyratory crusher is that the crushing process is carried out continuously along the annular crushing chamber, so the production capacity is larger. , lower unit power consumption, more stable operation, suitable for crushing flaky materials, and the particle size of the crushed products is relatively uniform。

Gyratory crusher can crush hundreds of materials

When the production volume of the factory is large and a jaw crusher for coarse crushing cannot meet the output requirements, a gyratory crusher should be used. Because when the feed particle size is the same, the output of a general gyratory crusher is more than twice that of a jaw crusher.

The crushing cavity of the gyratory crusher is deeper than that of the jaw crusher, and the crushing ratio is also larger. The machine crushing ratio of the gyratory crusher (the ratio of the width of the feed opening to the width when the discharge opening is adjusted to a small opening) reaches 6-9.5, and the larger the feed particle size, the greater the machine crushing ratio. The actual crushing ratio of the gyratory crusher (the ratio of the size of the feed or discharge material that can pass through the screen hole at 80%) is 4-5.

Advantages And Characteristics

中意旋回破优势

1. High breakage rate

Due to the higher crushing rate, the output product has smaller particle size. This reduces pressure on the belt conveyor transfer points, thereby reducing material handling costs, reducing downtime and reducing maintenance costs.

2. Simple process

The special design means that the crusher will not be oversaturated with material, simplifying the design of the production line and eliminating the need for transition piles.

3. Large feed particle size

Spherical bearings enable stronger eccentric motion within the crushing chamber, allowing for efficient crushing of very large feed materials.

4. Can break hard abrasive materials

The heavy-duty swing design is ideal for crushing harder, abrasive materials like iron ore.

5. The product has good grain shape

The special lining plate and crushing cavity structure can produce more valuable cubic block products and reduce the output of fine particles.

6. Low maintenance cost

The use of spherical bearings, instead of bushings, eliminates point loading in this area - extending bearing life, reducing downtime and reducing maintenance costs

7. The ore discharge port is adjustable

Spherical bearings allow for smaller discharge openings, resulting in smaller product sizes at higher settings.

8. Rotatable rack

Hydraulic separation and overall replacement of the frame (including fixed cone liner) make maintenance more convenient and safer. Using the new frame and fixed cone liner, maintenance downtime is reduced by 60%.

旋回破碎机生产现场

时产万吨玄武岩破碎项目采用中意旋回破

Project name: Basalt gravel production line with daily output of 10,000 tons

Raw material: basalt

Equipment used: gyratory crusher, cone crusher, vibrating screen

Finished product requirements: three types of aggregates 0-31.5mm

Production requirements: 10000T/H

Granite gravel production line with an output of 7,000 tons per hour

Zhongyi Mining Machinery sales engineers have discussed and communicated with customers many times and formulated a combination plan of gyratory crusher + cone crusher + sand making machine + vibrating screen. This model can meet the basic demand of 7000t/h output and can avoid the need to reach the output. The use of multiple devices in series may result in an unsafe situation where the site's access area is too narrow.

Working Principle

旋回式破碎机内部结构

Working principle of gyratory crusher

Zhongyi gyratory crusher consists of upper frame, middle frame, moving cone parts, lower frame, eccentric parts, transmission part, hydraulic part, etc. When the equipment is working, the motor drives the horizontal shaft to rotate, and the horizontal shaft drives the eccentric sleeve to rotate through the gear, and then the eccentric sleeve drives the moving cone to swing in a circle, thereby achieving continuous extrusion and crushing of stones. The size of the ore discharge port can be changed by adjusting the hydraulic cylinder at the bottom of the moving cone to facilitate adjustment of product particle size; at the same time, the hydraulic cylinder also provides iron protection function. When an unbreakable object enters the crushing chamber, the hydraulic cylinder can automatically make the moving cone fall. Release objects and protect the crusher.

Technical Parameter

| Model | Feeding port size(mm) | Installed power(kw) | Maximum capacity(Mtph ) |

| XHZ42-65 | 1066 | 450 | 5250 |

| XHZ50-65 | 1270 | 450 | 6375 |

| XHZ54-75 | 1370 | 600 | 7500 |

| XHZ62-75 | 1575 | 600 | 8750 |

| XHZ60-89 | 1525 | 750 | 12500 |

| XHZ70-89 | 1780 | 900 | 15000 |

| XHZ60-110 | 1525 | 1500 | 17000 |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)