- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

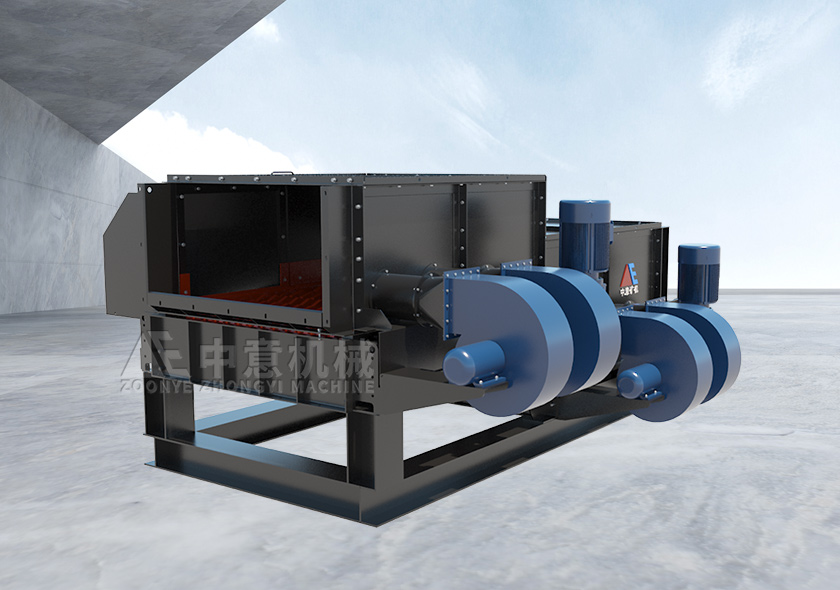

Roller Screen

Processing Capacity:200-300t/h

Feed Particle Size:800-1000mm

Applicable Materials:Construction and decoration waste, river pebbles, limestone, cobbles and other materials

Application Scope:Metallurgy, chemical industry, building materials, coal, construction waste disposal sites, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

The roller screen is a sorting equipment that separates different sizes and shapes through the rolling of discs. By adjusting the gap of the discs, materials with large differences in size can be effectively separated. The processing capacity of the disc screen is 4 times that of the traditional drum screen with the same volume, and the screening efficiency is twice that of the drum screen.

Double layer roller screen

Roller screen manufacturer

Zhongyi new roller screen

GZS1440 roller screen

Actual shot of roller screen factory

Beautiful photos of roller screen

The mobile roller screen ordered by Mr. Liu from Zhejiang was shipped.

Roller screen + drum screen delivery

Advantages And Characteristics

Roller screen performance advantages

1. The processing capacity can reach 300t/h;

2. The disc pair structure is used to set the sieve hole size, 25~120mm sieve holes are optional, and all can be customized to design and produce;

3. It can replace the drum screen, the processing capacity is 4 times that of the traditional drum screen with the same volume, and the screening efficiency is 1.5 times that of the drum screen;

4. It adopts variable frequency drive control method, which has low energy consumption, high safety and adjustable processing capacity;

5. Special wear-resistant sprocket, chain linkage, tensioned chain design, high operating stability;

6. Modular design, the appropriate number of modules can be selected according to customer requirements to facilitate maintenance and structural adjustment;

7. The production capacity and sorting effect have greatly surpassed traditional screening equipment such as drum screens, rod screens and vibrating screens;

8. Suitable for all types of solid waste, such as construction and decoration waste, domestic waste, stale waste, food waste, etc.

Working Principle

The roller screen is used to separate materials smaller than the specified size. The screen plate adopts a butterfly-shaped structure and is equipped with a uniformly distributed rotating shaft. There are several screen plates along the axial direction of the rotating shaft. The surface of the screen plate is made of ceramic spray paint, which is anti-corrosion and wear-resistant. Double effect. The rotating shaft is driven to rotate by the driving equipment. After the material enters the equipment, the material larger than the gap of the screen plate is transported from the top of the screen plate to the next process. The material smaller than the gap of the screen plate falls from the gap to the collection belt below and is transported out by the collection belt. equipment. In addition, Zhongyi roller screen is also equipped with multiple fans, which greatly improves the separation effect of light substances.

Roller screen manufacturer

With the rapid development of industrialization, the market demand for roller screens is increasing, and there are more and more manufacturers producing roller screens. So the question is, how to choose a reliable manufacturer among the many roller screen manufacturers?

When users purchase a roller screen, it is very important to consider the roller screen manufacturer. Only by choosing the right roller screen manufacturer can production efficiency be more guaranteed. Zhengzhou Zhongyi Mining Machinery is a powerful manufacturer that produces and sells roller screens. The roller screens it produces have high transmission efficiency, low energy consumption, and are not easy to block. They have low vibration noise and are easy to maintain. They have high efficiency, large processing capacity, and long life. They are widely used in metallurgy. , chemical industry, building materials, coal, construction and decoration waste sorting and other fields are widely used. If you want to know the output, price, parameters, etc. of the roller screen, you can call the consultation hotline 135-2302-0101, or consult online or leave a message. Zhongyi Company will arrange professional sales engineers to answer your questions one-on-one.

Roller screen price

The price of the roller screen is an issue that users are more concerned about when purchasing machines. Everyone wants to buy high-quality and low-priced equipment, so they need to choose a manufacturer with a high cost-effectiveness. Zhongyi Mining Machinery not only has its own production workshop, but also implements a marketing model that combines online and offline. This not only greatly reduces customers’ time and energy in purchasing equipment, but also saves users a fortune in factory visits. Not only that, the cost of purchasing is not only that, the roller screens produced by Zhongyi Mining Machinery have a complete range of models and are made of thickened steel. They are solid and durable, and are truly high-quality and low-priced.

Good quality and low price, strong manufacturer

Technical Parameter

| Model | Power(kw) | Feed particle size(mm) | Throughput(t/h) |

| GZS1440 | 15+3+3+3 | 350 | 180-600 |

| GZS1840 | 22+3+3+3 | 450 | 350-1000 |

| GZS1440(出土) | 45-55 | 350 | 180-600 |

| GZS1420 | 37-55 | 330 | 150-500 |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)