- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

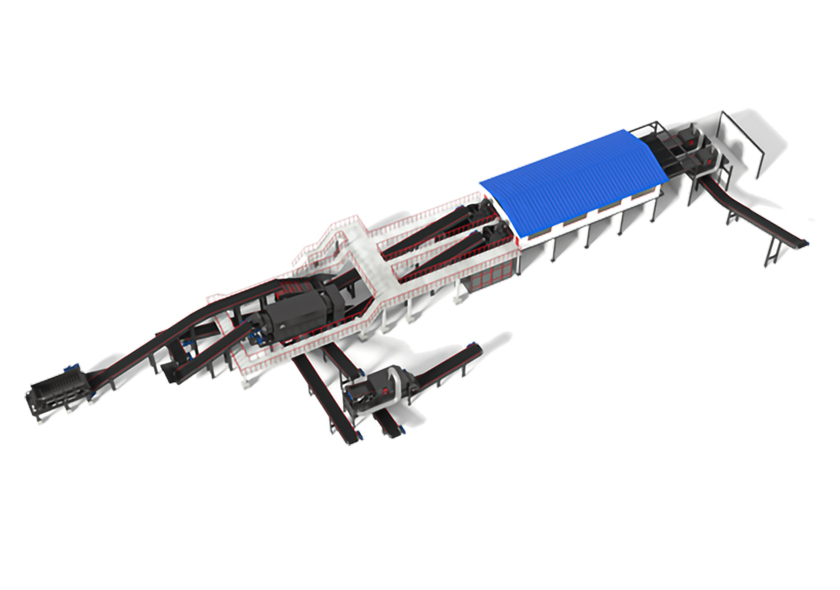

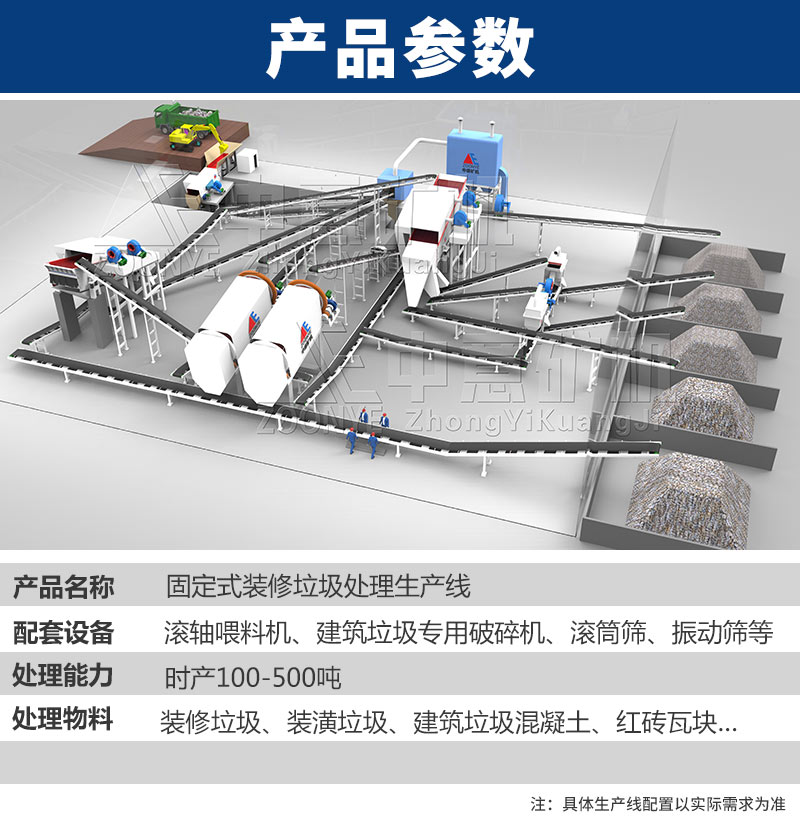

Fixed Decoration Waste Disposal Production Line

Processing Capacity:100-500t/h

Feed Particle Size:≤1000mm

Applicable Materials:Renovation waste, decoration waste, construction waste concrete, red bricks and tiles...

Application Scope:Property management, solid waste treatment, urban construction waste treatment...

- +8613503852957

- 7 * 24-hour Service Hotline

With the rapid development of my country's social economy, the acceleration of urbanization, and the rapid improvement of people's living standards, the garbage and waste generated in the process of urban production and life have also increased rapidly. Decoration waste has caused land occupation, soil damage, and pollution. Water bodies, polluted air, impact on city appearance and potential safety hazards have aroused widespread concern from all walks of life. *Attach great importance to environmental protection issues and have made great progress in decoration waste. However, while the output of urban waste in our country continues to increase, the classification, recycling and processing capabilities and levels of decoration waste are relatively lagging behind. That is to say, my country's decoration waste treatment technology is very Weak, therefore the applicability of decoration waste treatment technology has become a very important issue in solving decoration waste.

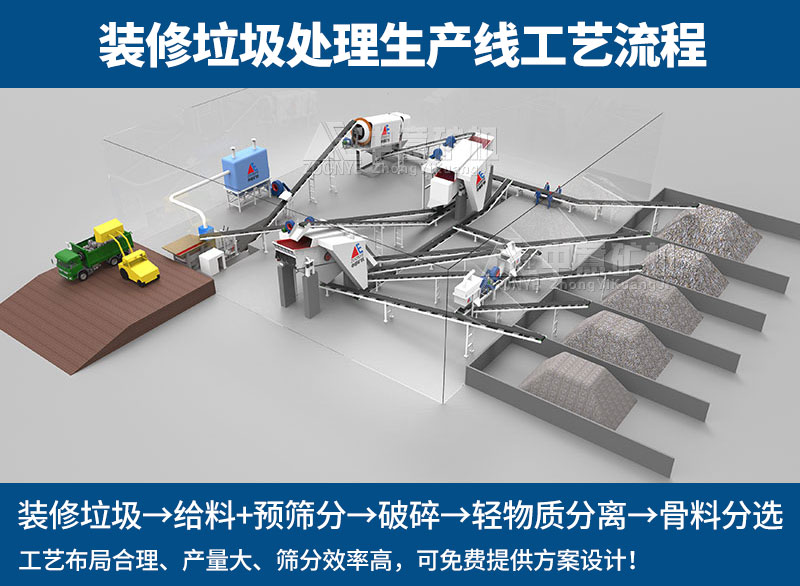

Decoration waste disposal production line

In order to solve the problem of urban construction and decoration waste and improve the harmlessness rate, reduction rate and resource utilization rate of garbage, Zhongyi Mining Machinery has launched a fixed decoration waste treatment production line after painstaking research. By processing construction and decoration waste into bricks, stones and Mechanical sorting of combustibles, crushing and screening, air separation of light materials, iron removal and manual sorting, washing and other processes can reduce construction waste into clean gravel aggregates, brick sand, screened soil, scrap iron, light Substances (including shredded wood, plastic, cloth, etc.) and other substances are then used to produce various types of recycled materials through brick making production lines and water-stabilized layer mixture production lines.

Turn decoration waste into treasure

The fixed decoration waste treatment production line will completely change the shortcomings of construction waste occupying land, destroying soil, polluting water bodies, polluting the air, affecting city appearance and safety hazards. Through sorting, crushing and recycling, it can achieve the reduction and resource utilization of construction waste. , harmless, to save resources, protect the environment, improve urban quality, develop circular economy, build a resource-saving society, and lay a good foundation for the comprehensive coordination, sustainable and steady development of the urban socio-economic environment.

roller screen

Double layer roller screen

construction waste crusher

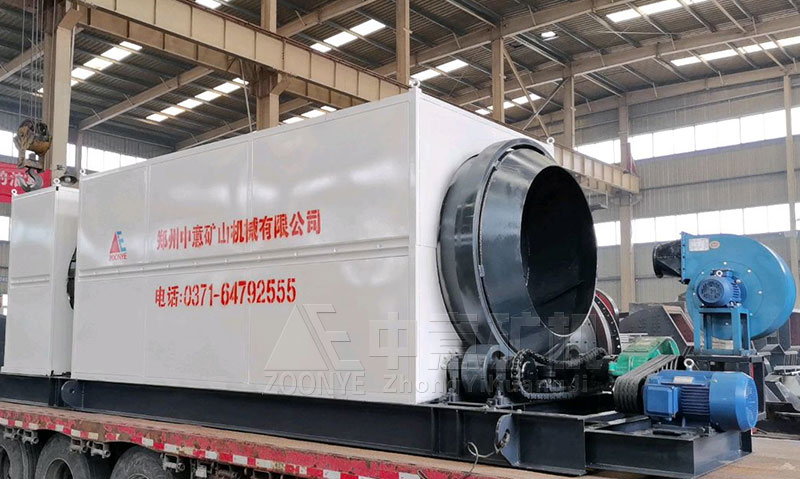

Trommel screen

Advantages And Characteristics

1. The integrated sorting equipment has a simple structure, is easy to manufacture and maintain, and has strong adjustment capabilities. It is suitable for different processing scales and is conducive to promotion and application.

2. The decoration garbage sorting machine has a large diameter, low rotation speed, smooth operation, low noise, small floor space, and easy installation.

3. The sorting efficiency is high, the sorting effect is obvious, the transportation cost is reduced, and the sorting process is simplified.

4. The entire production line is low-carbon and environmentally friendly. The main transmission belt adopts a fully enclosed structure to reduce dust and noise, and is equipped with a bag dust removal device and a dry mist dust reduction device.

5. Different models of machines can be used according to customer requirements, with long service life and low maintenance costs.

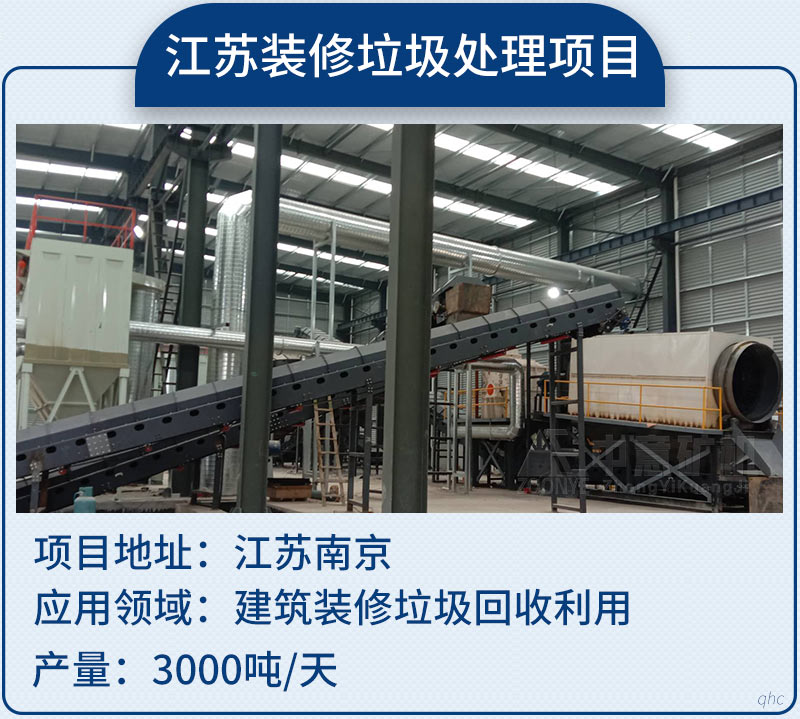

success cases

1. The renovation waste treatment production line with an annual consumption of 500,000 tons in Nanjing, Jiangsu has been put into operation stably. The entire production line is planned and designed under the guidance of green, circular, and low-carbon concepts. It adopts new renovation waste sorting equipment and dust removal equipment to reduce noise and dust emissions. Fully meet environmental requirements; through manual sorting, multi-layer screening and winnowing of decoration waste, different materials are classified, and the classified materials are processed as resources.

2. Zhejiang Environmental Protection Company has introduced 2 sets of renovation waste treatment equipment from Italy. The project includes the original decoration waste storage area, pre-sorting and separation area, loading area, sorting system operation area and terminal product collection area. It also has supporting systems such as fresh air dust removal system, fire emergency system, electrical control and maintenance workshop, etc. Decoration waste is processed in an integrated manner.

3. Anhui's daily 2,000-ton decoration waste sorting equipment has been put into operation stably. It not only solves the problem of how to place decoration waste, but also allows full utilization of resource recycling, saves costs, and can truly realize the resource utilization and harmlessness of decoration waste.

4. The construction and decoration waste recycling project in Chengdu, Sichuan transforms the traditional linear economic model of "resources-product-waste" into a closed-loop economic model of "resources-product-renewable resources" to promote the conversion of construction waste into green building materials , extend the industrial chain.

Working Principle

The forklift pours the decoration waste into the silo of the production line, and the feeder sends the raw materials evenly to the roller screen. Larger stones, plastic buckets and other waste are sorted out first. The remaining decoration waste is transported into the drum screen with the help of the conveyor belt, and is divided into medium and small categories according to the size of the holes in the drum wall. Light objects such as sacks and plastic films are blown out from the tail by the blower. At the same time, workers sorted out bulky waste on the conveyor belt. The stones and concrete blocks arrive at the construction waste crusher along with the conveyor belt. The crushed materials are then sent to the vibrating screen by the belt conveyor. The vibrating screen screens out two finished materials, and the remaining materials enter the fine crusher for crushing again. The finely crushed materials are returned to the vibrating screen for screening. The entire production line forms a closed loop with reasonable layout and large processing capacity. In order to separate light materials more thoroughly, fans are installed on both the roller screen and the vibrating screen. The recycling rate of decoration waste is over 90%.

The main structural components of the decoration waste treatment production line are:

The decoration waste treatment production line is mainly composed of a feeder, a roller screen, a construction waste crusher, a drum screen, an air separation vibrating screen, multiple belt conveyors, dust removal and noise reduction devices, and electronic control devices.

The decoration waste treatment production line consists of multiple equipment. As the core sorting equipment, the roller screen plays a very important role in the entire process. Compared with the traditional drum screen, the dynamic screen holes of the Zhongyi drum screen have a self-cleaning function, and the transmission shaft greatly reduces the possibility of entanglement of long pieces of garbage.

Technical Parameter

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)