- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

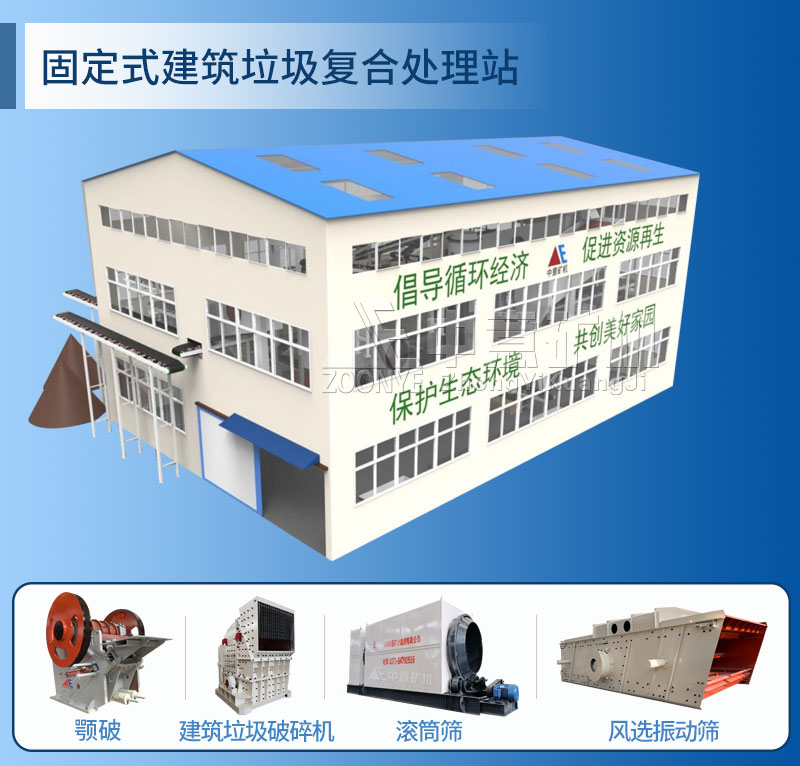

New Construction Waste Composite Treatment Station

Processing Capacity:40-1020t/h

Feed Particle Size:≤1500mm

Applicable Materials:Waste reinforced concrete, cement pile heads, concrete pavement, construction waste red bricks and tiles...

Application Scope:Construction waste recycled aggregate screening and deep processing, sand and gravel aggregate production...

- +8613503852957

- 7 * 24-hour Service Hotline

The new environmentally friendly fixed construction waste composite treatment station uses fixed crushing, screening, washing, air separation and other equipment to process construction waste in the factory. The entire production line adopts a closed design, and the achievable construction waste treatment is pollution-free.

Advantages And Characteristics

1. Suitable for deep processing of construction waste resources;

2. Build a large-scale construction waste treatment production line with a daily production capacity of more than 10,000 tons;

3. It can produce in a closed workshop and completely solve various pollution problems;

4. Can produce various recycled aggregates and achieve zero emissions;

5. The entire production line is equipped with dust removal and noise reduction devices.

6. The production line adopts microcomputer automatic control and has a high degree of automation.

Jiaozuo Qinyang Zhongyi Renewable Resources Production Site

Fujian Hejing construction waste treatment project

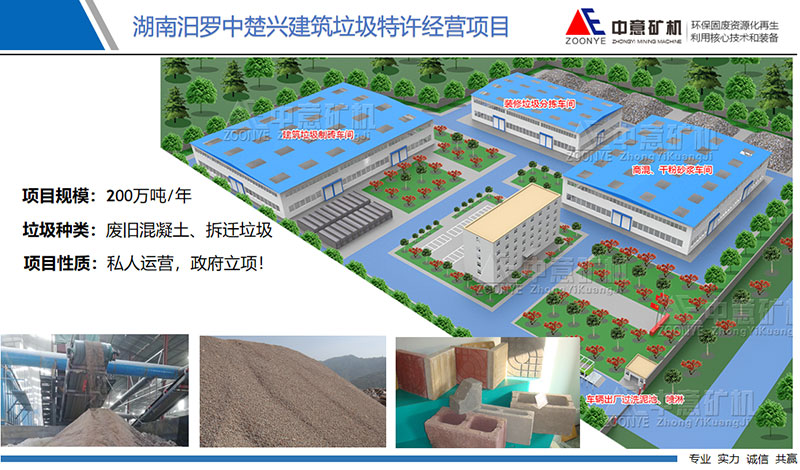

Hunan Miluo construction waste treatment project

Hubei Gongan County Construction Waste Treatment Project

Shanxi Xiaoyi Korfeng Company introduces Zhongyi Mining Machinery’s fixed construction waste crushing and brick making production line

Guizhou Weining purchases Zhongyi fixed construction waste composite treatment station

Working Principle

Stationary construction waste treatment process

1. The raw materials are poured directly into the silo by truck and evenly sent to the C-type jaw crusher through the vibrating feeder. C-type crusher is used for primary crushing of raw materials. Then use a belt conveyor to transport it to the special trash bin of the construction waste crusher.

2. Use trucks to send construction waste of brick-concrete structure (≤500 mm) directly into the silo, and use a vibrating feeder to evenly transport construction waste to a special crusher. The crushed materials (iron removal) are sent to the drum separator by the belt conveyor to separate the aggregates from the bulk materials. After sorting, the aggregates smaller than 140 mm enter the next process. Materials larger than 140 mm enter the air separation platform for light material removal and air separation, and the aggregates enter the special crusher for construction waste for further crushing. Materials smaller than 140 mm are transported from the belt conveyor to the second floor of the screening workshop for screening. The screening workshop has two screening systems, namely 0~10 mm sintered brick raw materials. In addition, the three types of aggregates of 10~20 mm, 20~30 mm and above 30 mm are separated into three negative air presses respectively. The air-separated aggregates are then transported to the flotation machine through a belt conveyor, and then Light materials are separated. The flotation materials enter the finished product screening system to separate 0-5, 5-10, 10-20, 20-31.5mm aggregates. Materials larger than 31.5mm enter the bottom of the single-cylinder hydraulic cone for crushing, and the broken materials and flotation materials enter together Finished product sieve.

Technical Parameter

| Equipment | FH2000 | FH3000 | FH4000 | |||

| Vibrating feeder | ZSW38095 | 11KW | ZSW4911 | 15KW | ZSW6013 | 30KW |

| Jaw Crusher | PE6090 | 75KW | PE7510 | 110KW | PE1012 | 160KW |

| Vibrating feeder | GZT1038 | 7.4KW | GZT1338 | 114KW | GZT1520 | 26KW |

| Construction waste crusher | PFW1310 | 132KW | PFW1314 | 160KW | PFW1520 | 440KW |

| Self-discharging iron remover | RCDD-8 | 4KW | RCDD-10 | 4KW | RCDD-10 | 4KW |

| Sorting machine | CTF1850 | 15KW | GTF2050 | 30KW | GTF2050(2台) | 60KW |

| Vibrating screen | 2YA1548 | 15KW | 2YA1860 | 18.5KW | 2YA2460 | 30KW |

| Vibrating screen | 3YA2160 | 30KW | 3YA2460 | 37KW | 3YA3275 | 45KW |

| Light material air separation separator | FX65 | 11KW | FX80 | 16.5KW | FX100 | 16.5KW |

| Light material flotation separator | FS80 | 11.5KW | FS150 | 15KW | FS150(2台) | 30KW |

| Vibrating screen | 4YA2160 | 30KW | 4YA2460 | 30KW | 4YA3275 | 45KW |

| Cone crusher | GP100 | 90KW | GP100 | 90KW | GP200 | 132KW |

| Electronic pulse bag dust collector | XM200+XM250 | 53.5+70 | XM200+XM250 | 70+105KW | XM250+XM350 | 70+105KW |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)