- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

YPC Mobile Construction Waste Crushing Station

Processing Capacity:50-300t/h

Feed Particle Size:≤1000mm

Applicable Materials:Waste reinforced concrete, construction waste bricks and tiles, cement pavement, cement pile heads...

Application Scope:House demolition, municipal road construction, burn-free brick factory, urban construction waste recycling...

- +8613503852957

- 7 * 24-hour Service Hotline

Mobile construction waste crushing and screening station manufacturer

The new mobile construction waste crushing and screening station technology developed by Zhengzhou Zhongyi Mining Machinery Co., Ltd. has stable performance. It has a high market share in domestic urban construction waste treatment. It is widely used in urban village demolition, old city reconstruction, road reconstruction and expansion, crushing and recycling of solid construction waste such as concrete and cement pile heads. Zhengzhou Zhongyi is one of the earliest enterprises in China to produce and sell urban construction waste crushing equipment.

Mobile construction waste crushing station

Sino-Italian construction waste shredded and sent to Guangdong

Neatly arranged mobile construction waste crushers

Mr. Zhou from Xi’an, Shaanxi purchased YPC series construction waste crushing and screening station

Ready-to-go mobile construction waste treatment equipment

Quote for large construction waste crushing equipment

New construction waste recycling equipment

Zhejiang Wenzhou Environmental Protection Company purchases construction waste crushing station

Successful cases of YPC mobile construction waste crushing equipment:

Jiaozuo Renewable Resources introduces Sino-Italian mobile crushing station

Shaanxi construction solid waste recycling production site

Hebei construction waste crushing and recycling case

Guangxi standardized construction and decoration waste treatment production line

Recycling of demolition waste in Hangzhou, Zhejiang

Guangdong construction waste crushing and screening production line

Beijing Daxing District adopts Sino-Italian mobile construction waste crushing station

Zhongyi mobile crushing station operation site in Shenzhen, Guangdong

Advantages And Characteristics

More than 95% of construction waste can be recycled through mobile crushing equipment, and its utilization value is mainly reflected in the following aspects: 1. Waste concrete blocks can be used as crushed aggregate for cast-in-place concrete or prefabricated elements and can be used in non-load-bearing parts of buildings. This not only saves construction money but does not reduce the strength of the structure. 2. Use waste bricks and ceramic tiles to produce aggregates, which can be used to produce recycled bricks, blocks, wall panels, floor tiles and other building material products. 3. For waste wood construction waste, wood that has not been significantly damaged can be directly used for building renovation, and seriously damaged wood components can be used as raw materials for wood recycled boards or papermaking materials. 4. Scrap steel, steel bars and other scrap metal materials can be directly reused or reprocessed. 5. Slag can be used in road construction, pile foundation filling, foundation, etc.

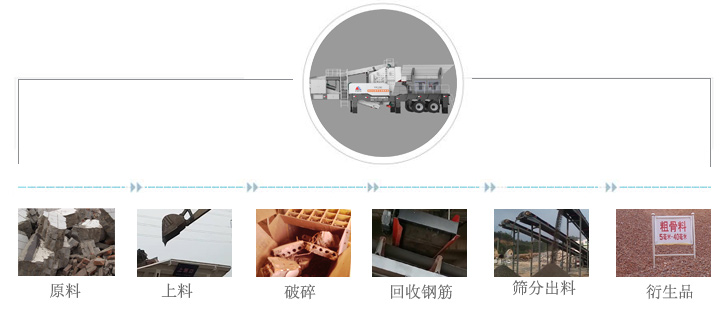

Working Principle

Mobile crushing station structure diagram

Construction waste treatment process

The raw materials are directly sent into the silo by the loader, enter the vibrating feeder through the silo, and are evenly transported by the feeder to a special crusher for construction waste treatment. The materials crushed by the special crusher for construction waste pass through the belt conveyor and are removed. The ironware is fed into the vibrating screen; the crushed materials are divided into three types of materials through the vibrating screen: 0~10 mm materials are transported to the finished product yard through a belt conveyor. Lumber and other debris are transported to the scrapyard via conveyor belt machines. The large materials are sent back to the garbage crusher through the conveyor belt for further crushing.

Technical Parameter

| Equipment | YPC120(Trommel screen configuration) | YPC200 | YPC260 | YPC300 | YPC350-400 |

| Function | Crushing and screening | broken | broken | broken | broken |

| Raw materials warehouse | YPC120 | YPCF200 | YPCF260 | YPC300 | YPC350 |

| Vibrating feeder | GZT1038 | GZT1038 | GZT1538 | GZT1838 | GZT2048 |

| construction waste crusher | PFW0810 | PFW1310 | PFW1314 | PFW1318 | PFW1520 |

| Crusher steel frame | PFW0810 | PFW1310 | PFW1314 | PFW1318 | PFW1520 |

| Belt conveyor (main belt) | B650=10m | B800=9.5m | B1000=9.5m | B1400=11m | B1400=11m |

| Belt conveyor (return material) | B500=14m | B650=9.3m | B650=9.3m | B800=10m | B800=10m |

| Drum screening device | GTS1548 | Optional | Optional | Optional | Optional |

| mobile frame | 12m(2 axis) | 12m(2axis) | 12m(2axis) | 13.5m(3axis) | 15m(4axis) |

| Steel structural parts | YPC120 | YPCF200 | YPCF260 | YPC300 | YPC350 |

| Belt conveyor (unearthed) | B500x3.2m | B500x3.2m | B650x3.2m | B650x3.2m | |

| Outrigger | YPC120 | YPCF200 | YPCF260 | YPC300 | YPC350 |

| Electric control cabinet | YPC120 | YPCF200 | YPCF260 | YPC300 | YPC350 |

| Cable | YPC120 | YPCF200 | YPCF260 | YPC300 | YPC350 |

| Automatic discharge iron remover | RCDD-6.5 | RCYD-8 | RCYD-10 | RCYD-12 | RCYD-12 |

| Return material short belt conveyor | B650=2.2m | 选配 | 选配 | 选配 | 选配 |

| Mobile belt conveyor | B500=10m | 选配 | 选配 | 选配 | 选配 |

| Iron remover steel frame | YPC120 | RCYD-8 | RCYD-10 | ||

| Hydraulic system | YPC120 | YPCF200 | YPCF260 | YPC300 | YPC300 |

| Power (kw) | 150kw | 166.1 | 241 | 370 | 514 |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)