- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

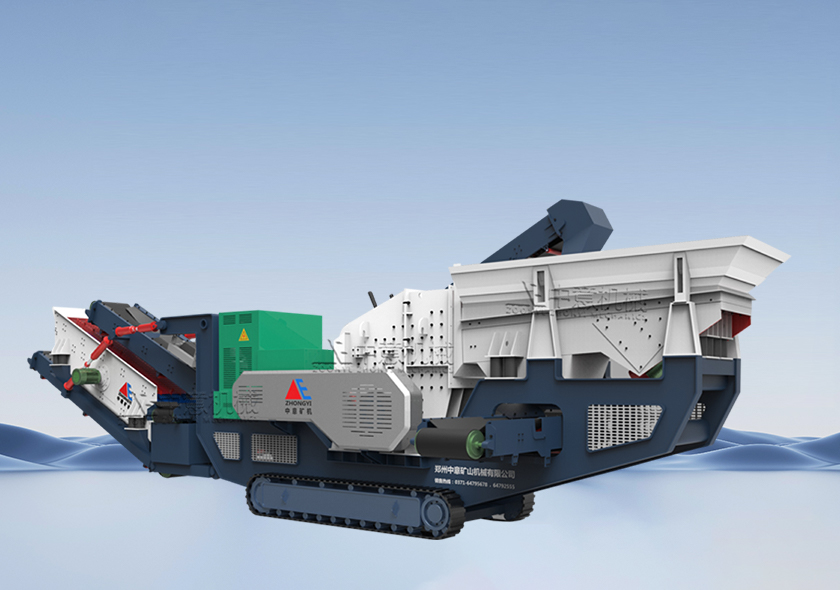

Crawler Type Crushing And Screening Machine

Processing Capacity:100-250t/h

Feed Particle Size:≤1200mm

Applicable Materials:Granite, basalt, rock, limestone, quartz stone, coal gangue, construction waste, etc.

Application Scope:Sand and gravel yard, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

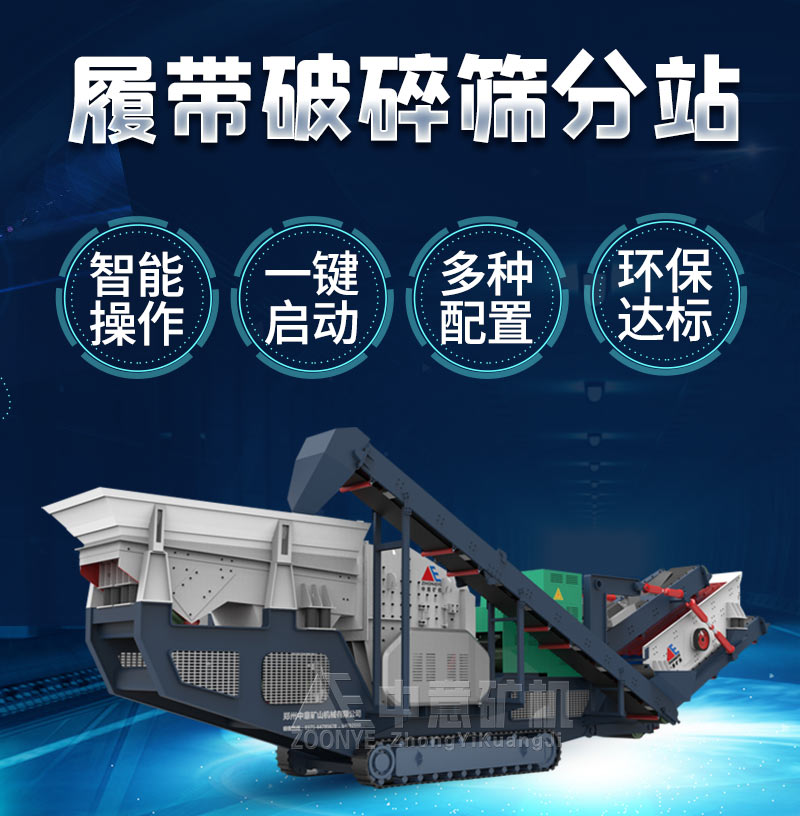

Crawler crushing and screening station

Crawler crushing and screening integrated machine, also called mobile crushing and screening integrated machine, is suitable for granite, basalt, rock, limestone, quartz stone, coal gangue, construction waste and other materials. This equipment is equipped with configurable jaw crusher, impact crusher, cone crusher, etc. It not only has the advantages of high crushing output, low cost, high versatility, and adjustable particle size of finished products; it can also ensure excellent particle shape and cleanliness of finished products. Meet the high standards required for construction aggregates. This equipment can be equipped with a vibrating screen, and one piece of equipment can crush and screen materials. It can also be combined with other equipment to complete the crushing and screening of materials in a mobile and efficient manner.

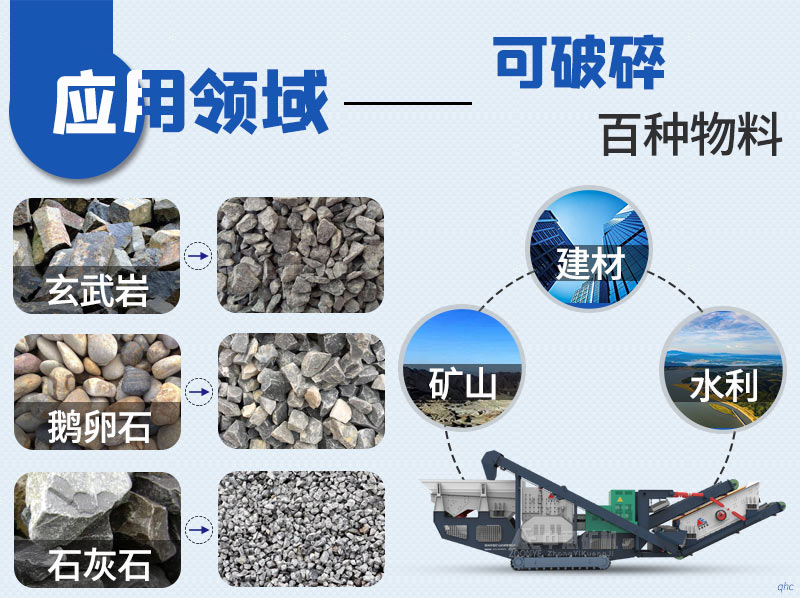

One machine can crush hundreds of materials

The integrated crawler crushing and screening machine is equipped with an easy-to-operate waterproof and dustproof control panel, which can monitor pressure, oil level, fuel consumption and control the crushing station crawler and feeding system. The equipment uses an innovative hydraulic system that can significantly reduce fuel consumption; the equipped pre-screening system not only makes the crushing efficiency higher but also effectively reduces equipment wear... The successful advent of the mobile crawler integrated crusher has greatly facilitated open-pit coal mines in my country, Mobile crushing meets the production requirements of road and bridge construction, urban construction and other industries. It is a new product that replaces traditional crushing equipment. It integrates material receiving, crushing, conveying and other process equipment into one, and is widely used in crushing operations such as rock crushing, aggregate production, and open-pit mining.

Product Image

Crawler crushing and screening integrated station

Crawler gravel machine

Crawler cone crushing station

Real shots of mobile crushing station manufacturers

Large mining mobile crusher manufacturer

Crawler rock crusher

Crawler crushing and screening integrated machine combination type

Diverse configurations, flexible

The emergence of the crawler-type mobile crushing station has greatly expanded the concept of coarse and fine crushing of stone. It stands from the user's perspective and strives to create a crushing equipment that makes users more satisfied based on convenience and high efficiency. The core structure of the equipment is composed of the main machine (crushing part), feeding, conveying and other systems. The main machine can be freely replaced. Systemically speaking, the equipment mainly includes crawler mobile jaw crushing station, crawler mobile impact crusher station, crawler mobile cone crusher station, crawler mobile station carrier, crawler standard screening mobile crushing station and other models. . Flexible model matching covers coarse crushing, medium crushing, fine crushing, screening and other functions. There is always one to meet your needs.

Advantages And Characteristics

1. Wireless remote control: Through wireless remote control, the equipment can be easily driven onto the trailer and transported to the working site. Intelligent operation is more convenient.

2. High operating efficiency: Adopting an integrated combined operation method, no assembly time is required, and you can start working immediately as soon as you arrive at the work site.

3. Supports mixed use of oil and electricity: This equipment can be equipped with a generator set to meet normal operating requirements in complex situations such as no power or power outage, ensuring continuous operation and reducing losses.

4. Environmental protection standards: The use of crawler mobile crushing stations is fully environmentally friendly and energy-saving, and many pollution factors such as loud noise and dust diffusion during the production process have been reasonably resolved.

5. Flexible and diverse configurations: multiple combination methods and multiple power types provide efficient solutions for crushing and screening materials.

6. All-steel ship-shaped structure: The chassis adopts a crawler-type all-steel ship-shaped structure, which has high strength, low grounding ratio, and can adapt to complex terrain.

What factors determine the price of mobile crusher

1. Manufacturer

With the popularity of domestic mobile crushers, mobile crushers from many manufacturers have appeared on the market, as well as foreign equipment. Of course, foreign prices are much higher than domestic mobile crushers. Small manufacturers are fighting a price war, but the quality of the equipment is not. Guarantee, large companies make conscientious equipment, the quality is guaranteed, and the prices vary, so the equipment manufacturer is one of the factors that determines the price.

2. Model

Before purchasing equipment, you must go through the steps when selecting. The model size of the equipment directly determines the investment cost of the equipment. The cost affects the equipment quotation. Therefore, different model sizes will also lead to different equipment prices.

3. Material selection

The production and manufacturing of equipment is the prerequisite for quality assurance. The quality of material selection also directly affects the cost investment. Zhongyi mobile crushers use high-quality materials to lay the foundation for users' later use.

Working Principle

The integrated crawler crushing and screening machine is commonly used for coarse crushing or medium and fine crushing of materials. The original materials pass through the vibrating feeder with pre-screening function. The small materials are filtered and discharged directly through the side outlet belt conveyor. The large materials enter the crushing chamber of the crusher. After being fully crushed in the crushing chamber, they are discharged through The belt conveyor transmits it to other equipment for the next step of crushing, or it can be directly discharged through the belt conveyor to complete the crushing operation. If the equipment is equipped with a vibrating screen, the materials will be crushed by the crusher and pass through the vibrating screen. Large materials will be returned to the feeder. Materials that meet the particle size requirements will be discharged directly through the discharge belt.

Technical Parameter

CPP series crawler impact screening station technical parameters | ||||

| Name | CPP200 | CPPS200 | CPP260 | CPPS260 |

| Crusher model | PFW1310 | PFW1310 | PFW1314 | PFW1314 |

| Crusher inlet size(mm) | 1060×1200 | 1060×1200 | 1460×1200 | 1460×1200 |

| Crusher discharge opening size(mm) | 20-80 | 20-80 | 30-100 | 20-100 |

| Feeder model | GZT1038 | GZT1038 | GZT1538 | GZT1538 |

| Feeder length(mm) | 3800 | 3800 | 3800 | 3800 |

| Feeder width(mm) | 1000 | 1000 | 1500 | 1500 |

| Feeding height(mm) | 4400 | 4400 | 4500 | 4500 |

| Main belt conveyor discharge height(mm) | 3000 | 2800 | 3000 | 2800 |

| Side discharge belt conveyor discharge at high speed(mm) | 1600 | 1600 | 1600 | 1600 |

| Screen box model | YK1332 | YA1535 | ||

| Screen box length(mm) | 3200 | 3500 | ||

| Screen box width(mm) | 1300 | 1500 | ||

| Throughput(t/h) | 100-200 | 100-200 | 150-250 | 150-250 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)