- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

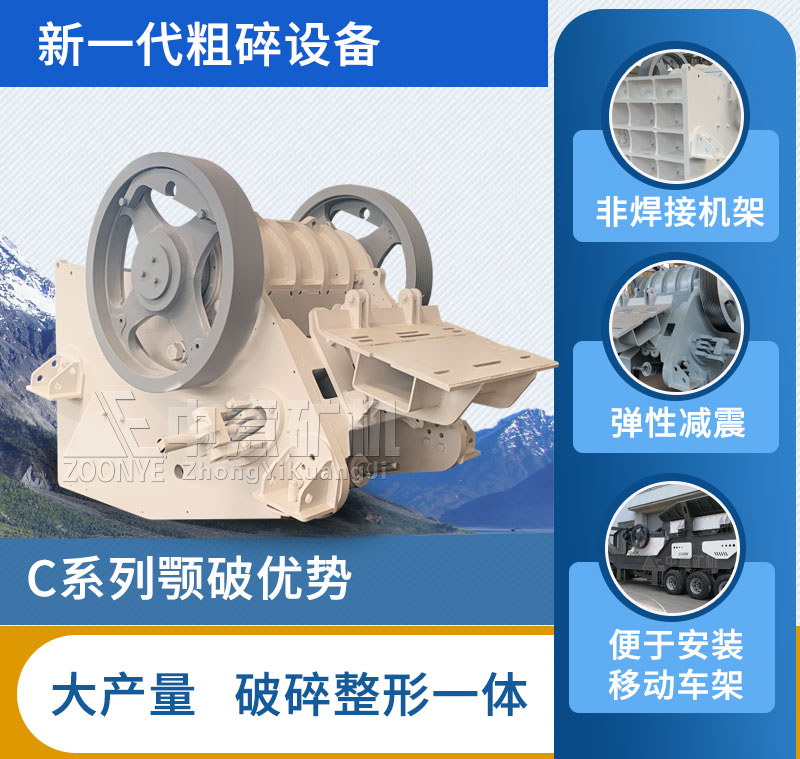

C-type Jaw Crusher (special For Mobile Station)

Processing Capacity:55-1575t/h

Feed Particle Size:≤1200mm

Applicable Materials:Granite, basalt, diabase, limestone, dolomite, iron ore, manganese ore, gold ore, copper ore, etc.

Application Scope:Sand and gravel yard, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

C type jaw crusher

Mobile jaw crushing stations have become an effective player in current sand and gravel processing, construction solid waste recycling and other projects. With customers' high requirements for output, mobile jaw crushing stations have also fallen into a development bottleneck. Traditional high-volume single jaw crushers are difficult to transport at high speeds when mounted on a mobile frame due to their large dimensions. In order to solve the problem of low production efficiency of existing mobile jaw crushers on the market, Zhongyi has developed the C-type jaw crusher, which is a model specially designed for mobile stations. Its equipment structure, use functions and production efficiency and other indicators They all reflect the level of modern technology, innovative appearance design, small footprint, and meet high-speed transportation conditions.

Zhongyi C type jaw crusher

Large-capacity jaw crusher, special mobile station design

Innovative appearance design facilitates mobile station installation

C type jaw crusher workshop display

The processing capacity of Zhongyi Mining Machinery C-type jaw crusher (dedicated to mobile stations) is between 55-1575t/h. It has a detachable and weldless structure frame, an optimized cavity structure, double wedge adjustment settings, selected raw materials and Components, elastic limit damping devices, integrated motor bases, etc. are specially designed to achieve high crushing efficiency, low investment cost, long service life, and stability.

Side view of jaw crusher

C-type jaw crusher customized by Guangdong customers

Solid, durable and easy to maintain

In order to ensure that the equipment can operate with high efficiency when crushing hard materials, the core rotating components of the C-type jaw crusher (special for mobile stations) include high-quality cast movable jaw body, heavy-duty forged eccentric shaft with large eccentricity, cast flywheel with high rotational inertia and high The strong overall cast steel bearing box, strong power and reasonable equipment speed ensure stable and efficient production of the equipment.

C type jaw crusher manufacturer

Mobile jaw crusher delivery

C-type jaw crusher can crush hundreds of materials

Advantages And Characteristics

1. Quick installation and rapid production

The C-type jaw crusher adopts an integrated motor base design to facilitate the installation of mobile equipment modules.

2. Easy to maintain and improve equipment operation rate

The equipment uses centralized grease lubrication, and a manual or automatic grease lubrication system can be configured as needed to reduce the difficulty of maintenance and ensure that the C series jaw crusher operating site is clean and tidy to the greatest extent.

3. High-quality casting and forging ensures reliable performance of equipment

High-quality raw materials and reliable design provide sufficient equipment strength and durability for the C-type jaw crusher to crush super-hard materials, and reduce maintenance costs.

4. Easy maintenance

The jaw plate is locked by a mechanical wedge, making it easy and quick to replace the jaw plate.

5. Easy to adjust

The C series jaw crusher uses double wedges to adjust the discharge opening, which can be adjusted mechanically or hydraulically as needed. It is simpler and more efficient than the traditional pad-type discharge opening adjustment operation.

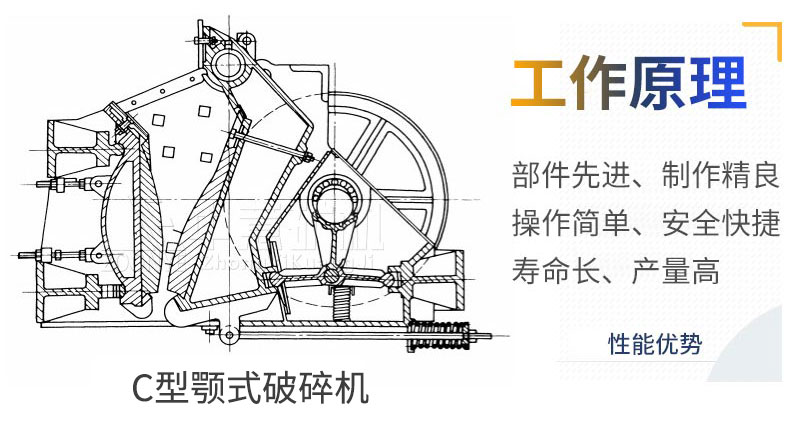

Working Principle

The motor drives the belt and pulley, and the eccentric shaft makes the movable jaw swing back and forth up and down. When the movable jaw pushes the movable jaw plate to move toward the fixed jaw plate, the material is crushed or chopped. When the movable jaw and the movable jaw plate retreat under the action of the eccentric shaft and spring, the previously crushed or chopped materials are discharged from the lower discharge port of the jaw plate. As the motor continuously rotates, the movable jaw of the crusher periodically crushes and discharges materials to achieve mass production.

Technical Parameter

| Model | Maximum feeding particle size(mm) | Discharge port range(mm) | Processing power(t/h) | Power(kw) |

| C80 | 410 | 40-175 | 55-370 | 75 |

| C96 | 460 | 60-175 | 105-430 | 90 |

| C106 | 560 | 70-200 | 150-560 | 110 |

| C116 | 610 | 70-200 | 165-580 | 132 |

| C120 | 700 | 70-175 | 175-595 | 160 |

| C130 | 800 | 100-250 | 270-915 | 185 |

| C150 | 960 | 125-250 | 340-970 | 200 |

| C160 | 960 | 150-300 | 430-1260 | 250 |

| C200 | 1200 | 175-300 | 630-1575 | 400 |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)