As a leading enterprise in the field of solid waste treatment equipment in China, Zhongyi Machinery has always taken the mission of "making solid waste treatment more efficient and environmentally friendly" to deepen the research and development of decoration waste treatment technology and the implementation of projects. The company's independently developed mobile crushing and screening machine adopts a modular design, integrates intelligent control system and noise reduction and dust removal device, and can flexibly combine core components such as impact breaking and jaw breaking according to material characteristics, and the crushing efficiency is more than 30% higher than that of traditional equipment. In response to easily entangled materials such as wood and plastic in decoration waste, the shear crusher developed by the company completely solves the pain points of industry such as card machines and tool vulnerability through multi-axis linkage design and special alloy tools. It has achieved large-scale application in solid waste disposal centers in Guangdong, Jiangsu and other places.

Technical breakthrough: Building a full-chain processing system

1. Intelligent sorting and precision breaking

The AI visual recognition system developed by Zhongyi Machinery can quickly distinguish wood, plastic, metal and other materials in decoration garbage, with an identification accuracy of more than 95%. With a dual-axis shear crusher, the material can be crushed to a particle size range of 0-150mm at one time, effectively solving the problems of easy material chokes and fast tool loss in traditional equipment. For hard materials such as concrete blocks, the GEF series impact crusher launched by the company adopts a heavy-duty rotor design, with a processing capacity of 210-550 tons/hour, and a uniform discharge particle size, meeting the production needs of recycled aggregates.

2. Environmental protection and energy efficiency optimization

Multi-stage dust removal system: The equipment is equipped with a pulse bag dust collector, and the dust emission concentration is less than 10mg/m³.

Noise reduction design: Through flexible connections, sound insulation cover and shock absorbing base, the noise is controlled below 75 decibels, adapting to sensitive scenes such as residential areas.

Intelligent monitoring: IoT technology monitors equipment operation data in real time, improves the accuracy of fault warning to 90%, and reduces maintenance costs by 28%.

3. Modular and mobile innovation

In response to county markets and temporary construction scenarios, the company has launched a mobile crushing and screening machine that integrates crushing, screening and iron removal functions, which can directly deal with decoration garbage on site, reducing transportation costs and secondary pollution. This equipment has achieved precise separation of concrete blocks, wood and plastics in the 800,000 square meters project of Jiangsu Yuankang, saving over 10 million yuan in annual landfill costs.

Case demonstrates strength, and full-process services create value

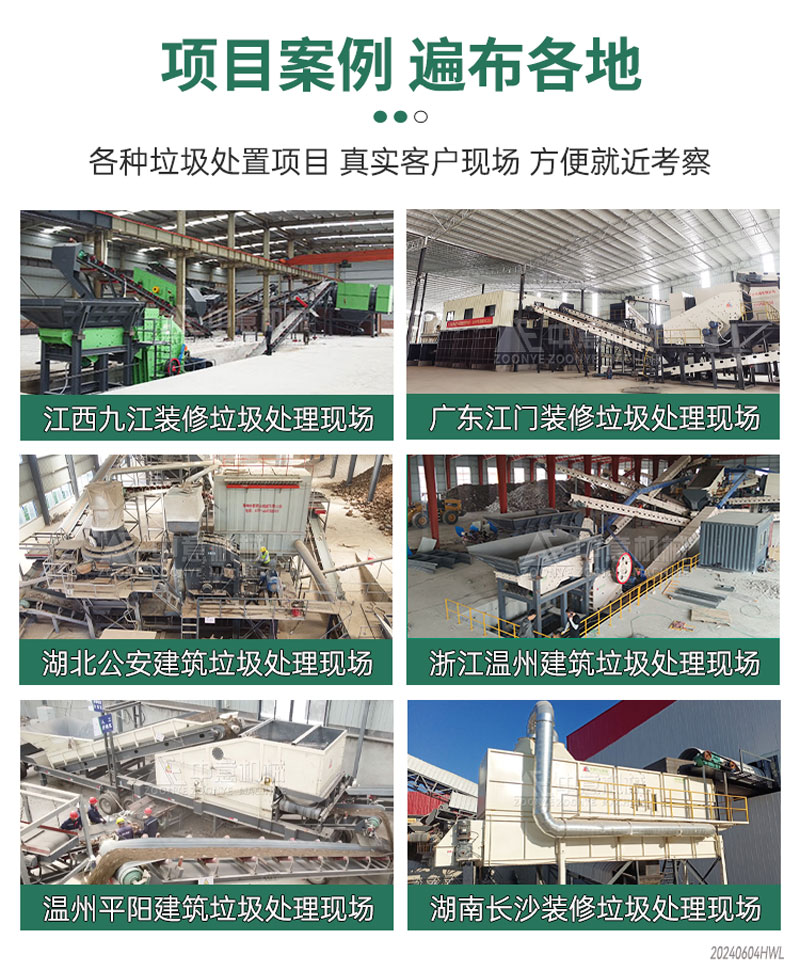

1. Hunan: Annual treatment of 2 million tons of construction solid waste projects

The project adopts the "crumbing + screening + air selection" process. Through the TTS series bounce screen and mobile crushing station customized by Zhongyi Machinery, the precise separation of concrete blocks, wood and plastics is achieved. The metal recovery rate is 95%, and the recycled aggregate is used for brick making, saving over 10 million yuan in annual landfill costs. The intelligent monitoring system equipped by the project can remotely adjust parameters and adapt to the decoration waste disposal of different components, becoming a project for resource utilization in central China.

2. Hubei: Annual processing of 1 million tons of EPC projects

As a model of the "turnkey" project of China-Italy Machinery, the project covers the entire process services of process design, equipment supply, installation and debugging. Through the combination of chain plate feeder + rod screen + integrated air selector, 90 million recycled aggregate blocks and bricks are produced annually, with a resource utilization rate of more than 90%. The project covers an area of 60 mu, adopts indoor production mode and sealing device, with dust emission concentration below 10mg/m³ and noise control below 75 decibels, achieving a double breakthrough in environmental protection and efficiency.

3. Zhejiang: Annual treatment of 600,000 tons of "waste-free city" demonstration project

The three-stage crushing + three-stage screening + three-stage air selection production line customized for this project, through intelligent sorting and photoelectric sorting technology, 99% of the resource utilization of decoration waste is achieved. The project is equipped with a high-definition camera device and intelligent reservation and transportation system, which can monitor the production process in real time, helping customers save more than 200 mu of landfill for annual land, and has been awarded the title of "Circular Economy Demonstration Unit" by the local government.

China-Italy Machinery continues to expand its overseas market and its products have been exported to more than 30 regions including Russia, Saudi Arabia, Vietnam. In 2025, the company provides sand and gravel treatment equipment for the port of Manila, Philippines, integrates core units such as spiral screens and bounce screens, and adopts military-grade earthquake-proof packaging and Beidou intelligent positioning system to ensure cross-border transportation safety. In the Southeast Asian market, the company cooperates with local enterprises to build a decoration waste resource project to promote the development of regional green industries through the "equipment-processing-application" closed-loop model.

Zhongyi Machinery has always aimed at "resource-based, harmless, and reduced quantification", and through technological innovation and full life cycle services, it will help urban decoration waste control to transform to intelligent and low-carbon. If you need to know more solutions, please visit the official website of Zhongyi Machinery or contact our technical team.