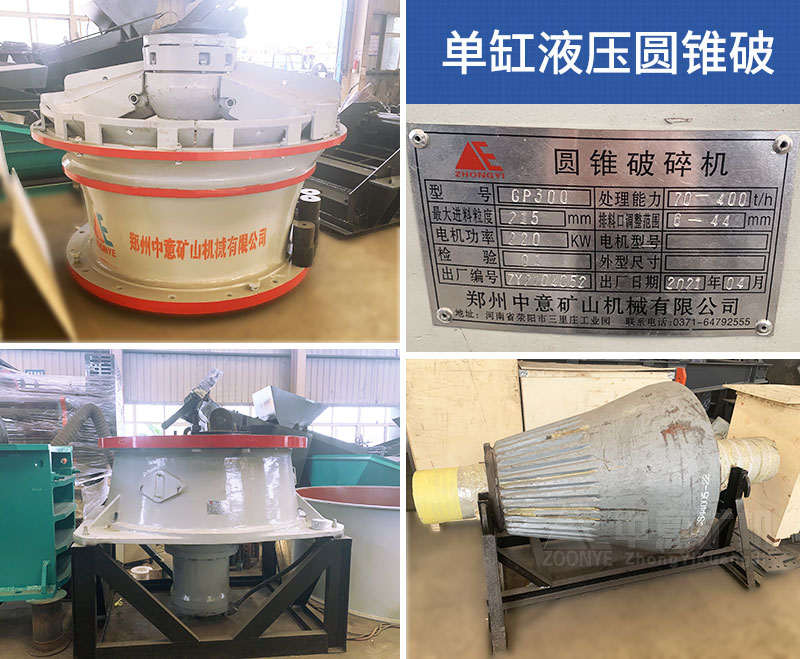

GP300 Bottom Single Cylinder Hydraulic Cone Crusher Exported To Africa And Successfully Shipped

- Handling materials:Basalt, granite and other raw materials

- Processing Power:300 tons/hour

Zhongyi Engineers Help Solve All Problems.

Online ChatCase Introduction

May is off to a good start, with Zhongyi sand and gravel equipment continuing to deliver goods! During Labor Day on May 1st, the GP300 bottom single-cylinder hydraulic cone crusher exported to Africa by Zhongyi Mining Machinery was successfully packed and shipped. Multiple sets of equipment will be shipped to Africa in the future, and it is expected that all shipments will be completed before the end of this month. In order to ensure the delivery of this export product, all departments of the company attach great importance to it. The production technology department inspected the quality details of the products before leaving the factory and imposed strict requirements on delivery precautions. This shipment marks a new step forward for Zhongyi Mining Machinery’s crushing equipment to enter the world again.

The GP300 bottom single-cylinder hydraulic cone crusher exported to Africa this time integrates mechanical, hydraulic, electrical, automation, intelligent control and other technologies, and can be widely used in medium, fine and ultra-fine crushing operations in the sand and gravel industry. This model has a processing capacity of 70-400t/h, and the adjustment range of the discharge opening is 6-44mm. It adopts the laminated crushing principle to achieve higher crushing efficiency, better particle shape of the finished product, and longer service life of the liner. The integrated design of the hydraulic station and lubrication station saves equipment installation space; the high-pressure hydraulic system ensures the pressure margin required for normal operation of the equipment and improves the reliability of the hydraulic system. The intelligent automatic control system keeps the crusher in optimal working condition and realizes automatic compensation function for the wear of inner and outer cone lining plates.

Technological Process

1. Initial crushing

The raw stone materials are evenly fed by the vibrating feeder and sent to the jaw crusher for primary crushing;

2. Secondary crushing

The coarsely crushed materials are sent by a belt conveyor to the bottom single-cylinder hydraulic cone crusher for further crushing to reduce the needle content of the basalt materials. After crushing, they are screened by a vibrating screen. The materials that do not meet the specifications are returned to the crusher for crushing again. The qualified ones are sent to the sand making machine for fine crushing;

3. Sand making

The material after secondary crushing is sent to the sand making machine by a belt conveyor for further crushing and shaping to reduce the content of needle flakes and internal cracked gravel in the material. It is then screened by a vibrating screen, and those that meet the specifications are sent to the washing machine. The sand machine is cleaned, and the sand that does not meet the specifications is returned to the sand making machine for fine crushing;

4. Sand washing

The basalt material after being finely crushed by the sand making machine is sent to the sand washing machine for cleaning operations, and then transported to the finished product pile by the belt conveyor.

Customer Feedback

Since the year before last, our project has introduced multiple sets of equipment such as jaw crushers, bottom single-cylinder hydraulic cone crushers, and vibrating screens from Zhongyi Mining Machinery. Currently, the equipment is operating well, and the finished products are well graded and of high quality, which can meet the requirements of the mixing station. needs. The output and quality of the equipment are in line with our expectations, and the sales service is also very satisfactory. Whether it is pre-sales, during or after sales, they are very trustworthy. This cooperation has been quite successful and I hope there will be opportunities to continue cooperation in the future.

Related Cases

-

Qingjian Group's 200-ton-per-hour Sand And Gravel Aggregate Production Line Settles In Africa

-

Zhengzhou Zhongyi Sand And Gravel Production Line Equipment Is Sent To Malaysia Site

-

Cobblestone Sand Making Production Line With Daily Output Of 1,000 Tons Sent Abroad

-

The Mobile Jaw Crusher Is Sent To Colombia To Help Customers Complete The Sand And Gravel Production